Sampling valves

Sampling valves for sterile sampling from tanks and pipelines

Sampling equipment is used to ensure sterile and aseptic sampling. Disinfection is performed before or after sampling.

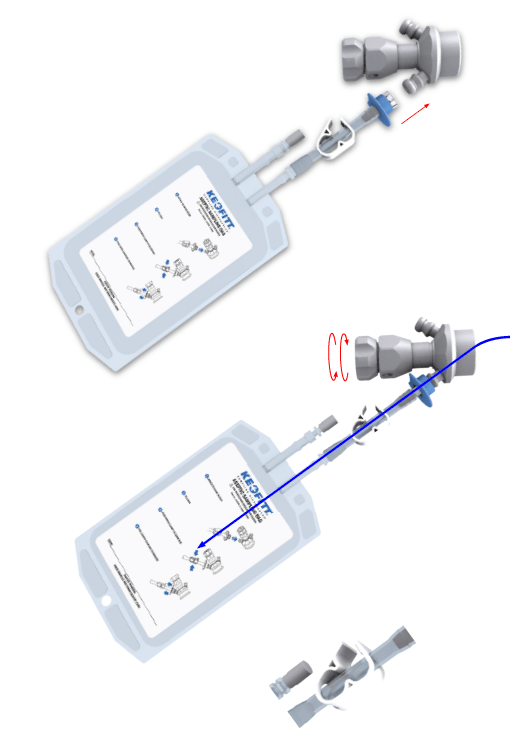

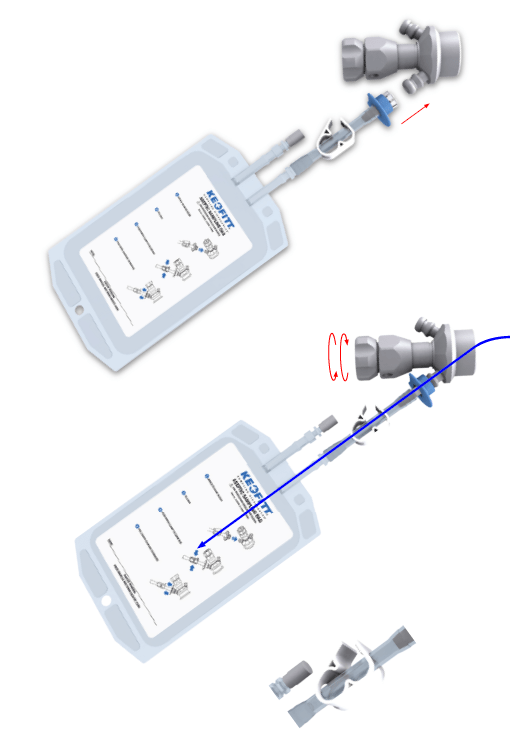

How does it work?

The sampling valves are based on the possibility of sterilizing them before and/or after each sampling, ensuring the reliability and purity of the analysis, regardless of the number of samples required to determine the quality and condition of the product.

Main parameters and advantages:

| Disinfection is carried out with steam or alcohol | Max. working pressure (closed): 10 bar |

| The medium is isolated directly by the membrane | Maximum disinfection temperature: 121~134C |

| The sampling method is typical | |

| The sampling valve prevents secondary contamination and allows for mass sampling or micro-sampling. |

The sampling valve consists of three main parts - the body, the lid and the rubber membrane.

The case happens:

- Design for low-viscosity products (water, wine, beer);

- Designed for high-viscosity systems (fruit yogurt, milk, syrup and ice cream).

Valve housings can be driven using various kinds of manual actuators, as well as using a pneumatic actuator.

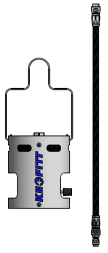

Individual systems are designed to meet specific needs and can be customized according to the system environment. The following versions are available:

- Valves for tanks

- T-shaped valves

- I-buildings

- Multi-way valve block

- Bottle sampling system

- Special valves

We also want to note that sampling is the initial stage of sanitary and epidemiological examination of food products, therefore, the representativeness of samples directly depends on the quality of sampling equipment.

In this way, the products are selected for further laboratory testing.

The sampling valves offered by Salutech are reliably sterilizable and meet hygienic and production requirements, which means that effective cleaning and sterilization by the sampler can be carried out independently of the production process.

The sampling valves are certified according to the sanitary standard 3A, which provides optimal conditions for food products during their possible contact with these components.

Call and order. Salutech will provide the necessary consultation in detail!