Centrifugal sealed pumps

Purpose of hermetic centrifugal pumps

A chemical centrifugal pump is an aggregate designed for pumping chemicals, including aggressive ones. The devices are not designed for pumping liquids with metallic inclusions.

Pumping equipment ensures tightness and absolute isolation of technological processes. The pumps guarantee the safety of personnel and the environment and prevent leakage of the pumped medium. The equipment is made of materials that do not affect the physico-chemical properties of the pumped substances. The pumps provide high flow accuracy and excellent performance indicators.

By design, centrifugal pumps can be:

- Horizontal and vertical;

- Monoblock and sectional;

- Single-stage or multi-stage;

- Submersible or cantilever.

The units ensure the stability of the flow of the pumped medium. Sealed pumps in explosion-proof design are available for operation in explosive atmospheres.

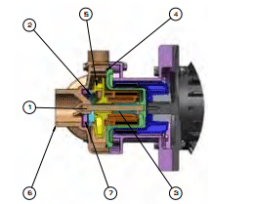

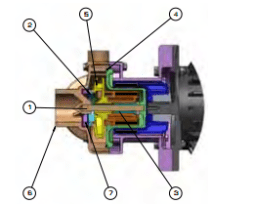

Design and principle of operation

The centrifugal pump includes an impeller with blades, which is mounted on the shaft and on the housing. The flow part, valves, valves, nozzles and other structural elements are also located inside the housing. The position of the shaft of the unit can be horizontal or vertical. The horizontal shaft arrangement is considered universal, vertical is found in semi-submersible and submersible centrifugal pumps.

The pumped liquid enters the flow part in the housing through a nozzle. The centrifugal force generated by the rotation of the shaft with blades throws the pumped medium onto the walls of the chamber. Under the influence of gravity, the liquid is ejected out through the pressure pipeline. A portion of the liquid is ejected, and a new batch enters the flow chamber. Polyamide seals provide high tightness and eliminate leakage.

Application of hermetic centrifugal pumps

The centrifugal sealed pump is designed for pumping the following media:

- The water is clean and polluted;

- Deonized and ionized water;

- Detergent-based solutions;

- Solutions of alkalis, acids, fluorocarbons;

- Organic solvents;

- Petroleum products and fuels.

Centrifugal pumps with a high level of tightness are used in the chemical, food, pharmaceutical, oil refining industries, metallurgy, mining and processing plants, and housing and communal services. The units are used in chemical laboratories, research institutes, where analyses and studies of various media are performed. Hermetic centrifugal pumps for explosive liquids are installed at gas stations, oil storage facilities, airport fuel storages, etc.

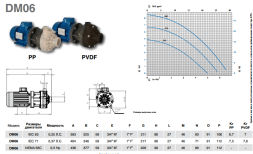

Where to buy sealed centrifugal pumps

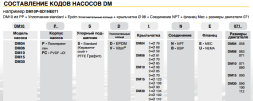

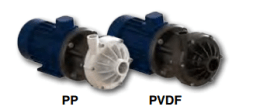

The Salutech company offers centrifugal hermetic pumps manufactured by Debem (Italy), Adonis (Russia). You can buy chemical pumping units with a capacity from 10 to 30 m3/h from us. The devices are certified and have passed pre-sale tests. The equipment is delivered to any region. The advantages of buying units in our company: qualified engineer advice and assistance in choosing, low prices, accompanying documentation, manufacturer's warranty, fast delivery. You can place an order for the purchase of a centrifugal chemical pump or get expert advice online or by phone.