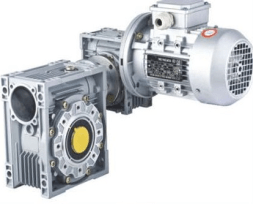

Worm gear motors

Worm gear motors include two mechanisms at once - an electric motor and a power reducer. They are used to equip conveyor structures, lifts, pumps and conveyors, and are used to equip sliding gates, compressor units and windscreen wipers in machine-building, metallurgical and agricultural industries.

Industrial worm gear motors are in demand wherever compact and inexpensive equipment capable of converting electrical energy into mechanical energy is required.

Types and features of worm gear motors

- Single–stage devices - a catalog of worm gear motors with a perpendicularly mounted input and output shaft. This type of equipment is the most in demand. It has a simple design and is characterized by increased reliability. A single-stage worm gear motor can be used in electric drive systems with both variable and constant loads. Its efficiency level reaches 70-80%.

- Two-stage gearboxes are used where a significant increase in torque and a decrease in shaft rotation speed are required. They are often installed in mechanisms for which high kinetic accuracy is especially important. A distinctive feature of two-stage worm gear motors is the possibility of increasing the gear ratio to several thousand units.

Key Features of NMRV Worm Gear Motors:

- improved layout, maintainability – small size, light weight, easy maintenance;

- comfortable operation - smooth running, low noise, vibration, self-braking effect;

- high gear ratio – worm gear motors of direct current have one of the greatest potential to increase torque when compared with other types of gears.

The high smoothness of such mechanisms is achieved due to the worm gear, and low noise is provided by the design features of the engagement. The shaft of the gear motor is absolutely stationary at rest. Therefore, if such a device suddenly stops when lifting a load, the shaft will automatically brake and prevent it from falling.

The most famous manufacturers of low-speed worm gear motors

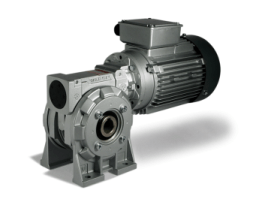

- Transtechno is a professional equipment from Italy. The brand manufactures gear motors in aluminum and cast iron housings, with a torque from 2400 to 3500 Hm.

- IDS is one of the largest Asian manufacturers. It produces gearboxes with high load capacities ranging from 0.06 to 7.5 kW.

- Motovario is an Italian manufacturer that pays special attention to shock absorption and noise protection of devices. The gearboxes of this brand have a modular design and are equipped with electric motors with a capacity from 0.09 kW to 55 kW.