Pressure reducers (regulators)

Pressure reducers will provide full control of the pressure in the pipeline

Pressure reducers (direct-acting control valves) compensate for changes in inlet pressure while maintaining a constant outlet pressure.

The main task of control valves is to constantly ensure stable outlet pressure for liquids or gases, while maintaining a balance between the pressure of the medium on the membrane or on the piston.

Pressure reducers (regulators) are indispensable in places where it is necessary to evenly distribute the medium along the entire length of the pipeline system, and they are also indispensable for the normal operation of equipment (reducing pressure and maintaining it in a given interval).

Pressure reducers also serve as a compensator for sudden pressure surges in the system (during hydraulic shocks), which can have the most unpleasant consequences for the system – from tearing off pipe fittings, for example, cranes and as a result flooding and damage to the heating system.

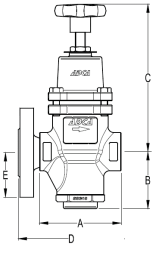

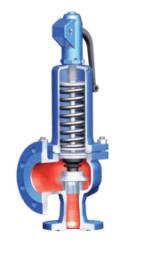

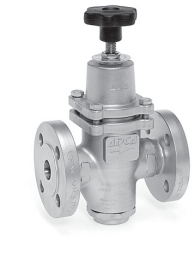

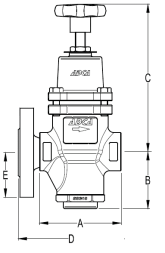

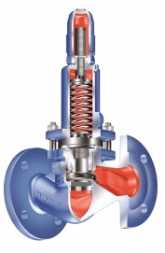

Pressure reducing valve designs

| Piston pressure reducers |

|

| Diaphragm pressure reducers |

|

Valve size selection and adjustment

The selection of the gearbox size is based on the set values to ensure the required performance and the diameter of the pipeline in which the valve is installed.

If it is necessary to reduce (reduce) the high pressure in the system to a low one, two pressure reducing valves must be installed in series.

There are various types of such valves:

- manual differential pressure regulators (flow rate);

- automatic differential pressure regulators (flow rate);

- direct-acting regulating valves "after themselves";

- direct-acting regulating valves "up to themselves";

- bypass valves.

Adjustment of pressure reducers (for all types of structures) occurs by changing the compression value of the adjusting spring with the adjusting screw. The adjustment of such pressure reducers takes place when the system is full and with the outlet valves closed, or on specially equipped stands.

Advantages of using gearboxes:

- extending the service life of pipeline systems

- the noise level of the pipeline network is reduced

- the costs and consumption of electricity from the use of pumping units are reduced.

Pressure reducers are used as technological devices for gas, petrochemical, metallurgical, chemical and other enterprises.

The purpose of direct-acting valves:

- Maintaining the integrity of hydraulic engineering equipment, pipelines and water collection devices, reducing the rate of leaks during flooding of premises with breaks in the system.

- Prevention of water hammer and prevention of exits from the working state of various measuring devices.

- To reduce wear on the valve seat, it is recommended to install a strainer in front of each valve.

- They are used in heating, ventilation, shipbuilding, water supply, etc.

In order to buy a pressure reducer, call the Salutech company or send a purchase by e-mail.

Call and order. Individual discount system for regular customers!