Brazed plate heat exchangers

The Salutech company offers brazed heat exchangers with delivery throughout Russia. Working directly with manufacturers allows you to provide a guarantee and keep the price below competitors by ten percent.

Design and technical characteristics of brazed heat exchangers

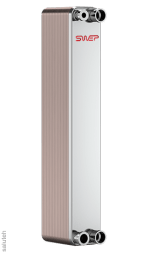

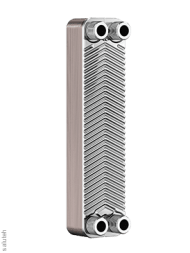

Its design consists of several plates interconnected by soldering. The structure is durable, non-collapsible, and has a monolithic outer casing. The corrugations made by stamping are located over the entire area of the brazed heat exchanger, which creates channels for the movement of the heated liquid. Soldering in a vacuum furnace provides the necessary hardness and water resistance. The efficiency of the heat exchanger, self-cleaning by internal flows depends on the model and the placement of the corrugation.

Technical characteristics of brazed heat exchangers:

1. Operating temperature: -10 to +180 degrees.

2. The maximum pressure is 25 bar.

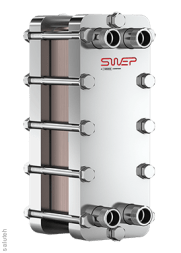

3. The method of connection is threaded, flanged.

4. The heat carriers used are water, steam, glycolic solutions.

5. Rubber seals are not used.

6. Aggressive environment is not suitable for their use.

Advantages and features of use

The brazed plate heat exchanger has the following advantages:

- small overall dimensions;

- quick installation and maintenance (carried out by pumping a special solution and subsequent rinsing);

- Similar in power, shell-and-tube heat exchangers are 90 percent heavier than brazed plate heat exchangers;

- they are adapted for long-term operation under severe temperature load;

- the delivery time of the order is minimal.

Fields of application of plate brazed heat exchangers

The equipment is widely in demand and is used in a variety of climatic and technological conditions. Areas of application:

- hot water supply for boiler houses and heating systems;

- swimming pools;

- thermal points;

- residential buildings, industrial facilities;

- food refrigeration equipment;

- the evaporator in the air conditioning equipment.

Our store offers a large selection of plate brazed heat exchangers. In order to select the most suitable and effective model, our specialists will make the necessary calculations in the shortest possible time.