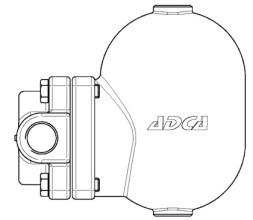

Float steam traps

The condensate trap is an important link between the condensate network and the steam consumption system. The main task of this device is the effective removal of air and condensate from steam installations and systems without loss of steam. These devices come in several types, but it is float steam traps that are widely used in the modern market.

Float flanged steam trap – purpose

Based on their purpose, the devices in question can be of 2 types. They may be intended for:

- Removal of excess moisture from steam condensate systems,

- Removal of moisture from pneumatic systems in which it accumulates during the preparation of compressed air masses.

Design and principle of operation of float steam traps

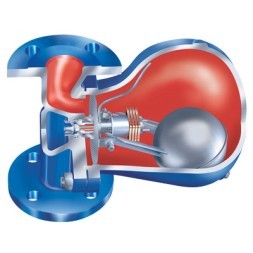

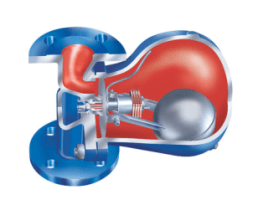

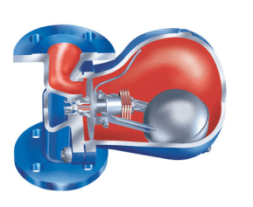

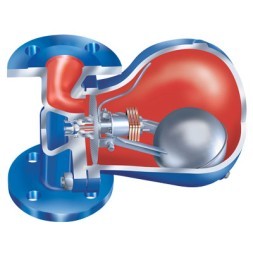

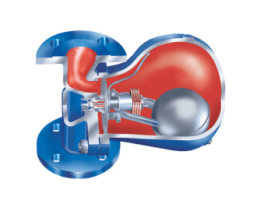

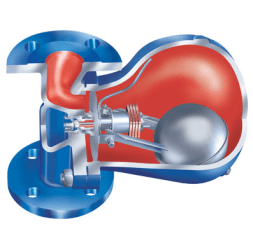

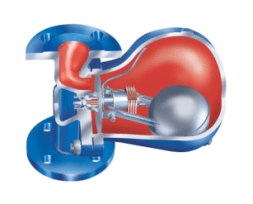

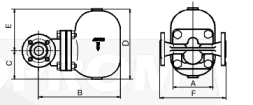

A standard float steam trap consists of the following main components:

- Float,

- Air vent (bimetallic element),

- Shutter seats,

- The shutter stem,

- Closure,

- Filter,

- Air outlet tubes.

The principle of operation of this device is based on the difference in the density of condensate and steam. During the absence of the medium, the float remains in the lower position, while the control rod of the shutter is at rest. The bimetallic air vent remains in a compressed position, thereby providing an outlet for incoming air masses.

In the case of steam entering the device and an increase in temperature values to 90 ° C, the stroke of the working rod is compensated by an increased bimetallic component. Thus, further closure/opening of the shutter is provided only by a float, which is connected to the lifting mechanism. During the increase in the condensate level, the float rises and the shutter opens. Inert gases and air are sucked out through the tube from the upper space by injection. After reducing the volume or complete disappearance of condensate, the float moves down and presses the shutter.

The scope of use of float steam traps

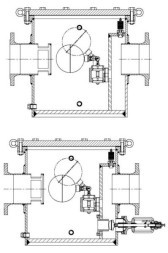

Mechanisms designed to remove steam and condensate can be used in:

- High-power heat exchangers,

- Steam distribution line,

- High-temperature parallel pipelines,

- Steam pipe drainage systems.

Key advantages of float steam traps

The Salutech company offers to buy a float steam trap for various purposes and tasks. The range includes products characterized by high manufacturing quality, reliability and durability.

Speaking about the key advantages of float steam traps, it is worth highlighting the following factors:

- The ability to discharge a significant amount of non-condensable gases (due to high throughput),

- The possibility of continuous discharge of the resulting condensate at high loads and pressure drops,

- Functionality (can be used when it is necessary to promptly empty steam lines),

- Ease of maintenance (when the amount of condensate or pressure drop conditions change, the control element is replaced without the need to replace the entire mechanism).

Buy float condensate drains in the company "Salutech"

The catalog of the Salutech company presents a wide range of equipment of this type. An adequate price for float steam traps is due to direct cooperation with manufacturers. The quality of the products is confirmed by the relevant certificates. If necessary, professional consultants will be able to help you choose the most suitable product option for a particular case.