Hydraulic safety valves

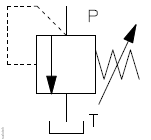

Hydraulic safety valves or CNG valves are a type of shut—off valves designed to protect hydraulic drive lines from excessive pressure. After discharging excess liquid or gas, the valve automatically returns to the closed position. Depending on the connection scheme and settings of the hydraulic valve, it can be safety or overflow.

The principle of operation of a pressure-controlled hydraulic safety valve

The simplest design of the hydraulic valve blocks the flow with a locking part. It is pressed against the saddle by an adjustable spring, less often by a lever. Such a valve opens when the pressure of the medium is higher than the pressure of the spring. After the forces of action are balanced, the spring automatically lowers the shutter.

The system can be improved by protecting the spring from environmental influences, control channels, a damper, a balanced lock, a second stage, a throttle and other elements.

Installation and adjustment of adjustable valves

You can adjust the valve by twisting the spring with a special screw. The principle is simple: the stronger the spring is initially compressed, the greater the force required to lift the shutter.

The operation mode of the hydraulic valve depends on the way the entire system is adjusted: through a pump or throttle. In the first case, it serves as a fuse and opens only in emergency situations. In the second case, the valve constantly passes a stream through itself, cutting off excess pressure.

Characteristics of hydraulic safety valves

Key Characteristics of the adjustable hydraulic safety valve:

- Mechanism of action: the rod can be lowered by a spring, lever or solenoid valve in combination with a spring.

- The nature of the trigger. Direct-acting valves wear out faster than two-stage valves.

- The maximum allowable pressure is usually in the range of 50 — 350 atmospheres

- The maximum flow rate is 35 — 600 l/min

- Installation of a safety regulating hydraulic valve is possible in a pipe, in a line, there are models on flanges and butt versions.

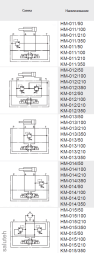

- The size is according to ISO 6264, ISO 4401 or in inches, according to the diameter of the pipe.

- The ability to adjust up to 3 pressure settings.

- Compatible liquids. As a rule, these are mineral oils and substances with similar properties. Sometimes — aqueous glycol, phosphoric ether and others.

Optionally, it is possible to install a valve handle or a button for adjustment instead of a turnkey screw, additional leakage protection. Additionally, the high-pressure hydraulic safety valve is equipped with an electromagnetic valve. This reduces the load on the plates and increases reliability.

For safety, the control screw can be sealed. The electronic control of the shutter allows purging or maintaining different pressures.

Areas of application of safety valves

Safety valves are needed in a variety of devices, from household water heating tanks to oil tanks. However, safety valves with adjustment are most in demand for hydraulic equipment: machine tool drives, presses, mobile equipment, foundry machines and other equipment.

When ordering adjustable safety valves with delivery, carefully study its characteristics. It is better to contact the company's manager to clarify all the details.