Plate heat exchangers

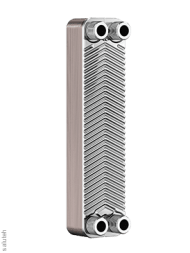

A plate heat exchanger is a device designed to transfer heat from a heat carrier to a heated medium through heat transfer plates. In the working position, the plates are pressed against each other and form slot channels. There are seals between the plates that prevent leakage of the coolant and the heat receiver. The plates are made of metals and their alloys that are resistant to corrosion. The thickness of the metal sheets used for the production ranges from 0.3 to 1 mm. The plates are produced using cold stamping technology. When adding plates, the heat exchanger increases its heating capacity, while removing it reduces it.

In our company, you can buy plate heat exchangers of two types:

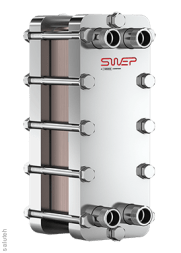

- With a collapsible design. This is a standard plate heat exchanger for an industrial or domestic boiler. The plate is installed between the frame and the pressure plates, which maintain the design pressure. The plates are made of sheet steel. To achieve the best thermal performance, the coolant and the heated liquid in most collapsible models flow through the heat exchanger in a countercurrent. Collapsible heat exchangers are designed for heat carriers whose temperature does not exceed +200 C and does not fall below -20 C. The maximum allowable pressure in the plates is 25 kgf/cm2. The devices have a high efficiency of at least 95%, which makes this type of plate heat exchanger the best for the price: 1 kW of energy is converted into a large amount of heat.

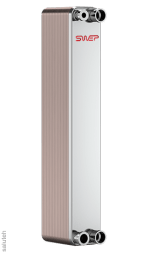

- With non-collapsible construction or soldered. Non-removable plate heat exchangers for heating are an all-welded structure. The devices do not have open gaskets. They are characterized by higher strength and a wide range of operating temperatures - from +900 to -100 C. The relatively high cost of non-collapsible plate heat exchangers allows them to be used to solve complex problems in the oil and gas, chemical industry, and energy. Non-removable devices have an efficiency of at least 85% and can withstand a coolant pressure of up to 4 MPa.

The principle and features of the plate heat exchanger

In the heat exchanger, the coolant and the heated liquid move countercurrent, i.e. towards each other. In the places where they flow, there is a plate or seal made of polyamide (rubber), which prevents the mixing of liquids. When flowing, the coolant gives off heat to the heated liquid.

In comparison with other types of heat exchangers, plate designs have advantages:

- High heat dissipation and performance;

- Small dimensions;

- The possibility of installing additional plates (for collapsible models);

- Reliability and reliability;

- Easy installation and maintenance (for collapsible ones);

- Resistance to corrosion, temperature changes and pressure;

- Low cost of heat generated.

The plate heat exchanger has the lowest price of 1 gigacalory of heat produced in comparison with other heat exchange designs.

The scope of application of plate heat exchangers

The plate heat exchanger for the heating system is used in food industry enterprises for heating liquids, pasteurization. The devices are used in the housing and communal services sector to connect structures and buildings to a centralized heating system. In industrial enterprises, heat exchangers are designed to recycle excess heat generated during technological processes.

Buy a plate heat exchanger in Moscow

The Salutech company offers delivery of plate heat exchangers in Moscow by our motor transport. Delivery to other localities and regions is carried out by transport companies in accordance with current tariffs. We have a wide range of models, favorable prices for plate heat exchangers are available, and a warranty is provided. You can place an order or get advice from a heating engineer online or by phone.