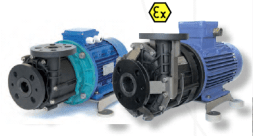

Chemical pumps

Chemical pumps: scope of application, varieties, device

Pumps for the chemical industry are designed for such engineering systems where liquid aggressive and chemically active compositions are used. To ensure the transportation of liquids through the system, it is necessary to connect a special powerful pump for chemical liquids. Conventional pumping units will quickly fail, they will not be able to guarantee the operability of the system, and specialized ones are characterized by increased resistance to petroleum products and other aggressive solutions. The stability of the units is explained not only by the use of special manufacturing materials, but also by structural features.

Design features

In production, such manufacturing materials are used that have proven high stability and do not collapse after contact with an aggressive substance. To ensure the durability of operation, the pump for pumping chemical liquids is made from:

- Steel alloyed with additional components: chromium, copper component, molybdenum, nickel;

- Ferro-silicon types of alloys;

- Titanium;

- Polypropylene raw materials.

Products made of these materials have proven resistance to chemical compositions, and it is easy to maintain normal operating pressure parameters in them. Not only the main element of the pump is made from persistent resources, but also the docking components connecting the working area to the engine.

The main design features are considered to be:

- Compliance with absolute tightness;

- Safety for the environment, employees of enterprises;

- Preservation of the original state of the liquid, without transformation of the structure and contamination by foreign inclusions;

- High EFFICIENCY: pumps for chemical media are characterized by high power and performance;

- Precision in work.

When creating units, the physico-chemical characteristics of the medium with which the pumping mechanism will be in contact, adaptability to specific conditions, and other features are taken into account, therefore, the price for chemical pumps cannot be the same as for conventional ones.

Scope of application

Specialized pumping units can operate with various aggressive liquids: petroleum products, paints and varnishes and solvents, flammable and explosive substances, alkalis, acids, radioactive components. It is also possible to pump gases and liquids with a temperature range from minus 40 degrees to plus 135 degrees. But the full list is much broader, more detailed information can be found in the instructions for using the installations.

The pump for chemical liquids is used in various industries:

- Chemical and gas industry;

- Food industry;

- Chemical and metallurgical industry;

- Pulp and paper, textile industries;

- Manufacture of paint and varnish products;

- Pharmaceuticals;

- Shipbuilding;

- Housing and communal services;

- Manufacture of refrigeration units;

- Nuclear power engineering.

Types of chemical pumps

The classification identifies many types of pumping devices, let's list the most popular types in this market segment and their features:

- The barrel pump for pumping chemicals is a simple unit, convenient to use. It can have an electric or pneumatic drive. They are made of stainless steel, aluminum, and polyvinyldenafluoride.

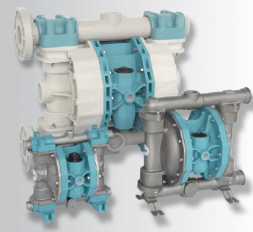

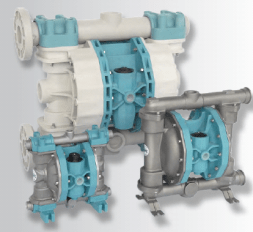

- A diaphragm pump is a volumetric device, the working element of which is considered to be a membrane or diaphragm. The equipment is characterized by high efficiency, a wide range of designs, high

- accurate dosing of the working substance, long service life, simple design and maintainability. Creates pressure with minimum cost.

- Vertical – compact and easy-to-maintain units, in which the impeller and shaft are located in a vertical plane. They are characterized by low noise levels combined with high

- efficiency.

- Horizontal devices are larger devices that take up a lot of space. The main elements are located in a horizontal plane.

It is most profitable to buy a chemical pump on the website of the Salutech company, where a wide selection of models of different types from the best manufacturers in the industry is presented. We cooperate with proven and reliable brands, we give a guarantee for all goods.