Thermodynamic steam traps

Thermodynamic condensate drains are designed to drain condensate in steam condensate systems. The devices are suitable for use in systems with high pressure and sudden temperature changes. Unlike other types of equipment with similar functions, the thermodynamic condensate trap is equipped with a thermal insulation cover, which ensures stable operation of the devices under adverse environmental conditions.

The equipment is installed for condensate drainage on main heat pipelines with a coolant in the form of steam, including saturated, superheated, with an admixture of gases. The devices are also used to drain condensate from heat exchangers.

The purpose of thermodynamic type steam traps is to remove condensate that forms in steam pipelines due to heat loss. The devices must be mounted at a distance of at least 30-50 m, depending on the quality and effectiveness of thermal insulation and climatic conditions. In this case, the first thermodynamic condensate drain must be installed behind the boiler and have a throughput capacity that is at least 20% of the boiler's capacity - with a steam pipe length of less than 1 km and 100% - with a steam pipe length of more than 1 km.

Advantages of thermodynamic steam traps:

- Condensate is removed immediately after its appearance;

- They do not need to be configured;

- Compact, light in weight;

- Easy to install and operate;

- Suitable for superheated steam;

- They do not deform and do not collapse when frozen;

- They have a minimum of moving parts in the structure;

- Resistant to hydraulic shocks;

- Equipped with a heat-insulating cover;

- The disc and seat can be replaced without disassembly.

According to the type of connection, the devices are divided into: coupling, flanged and welded. Thermodynamic flange-type steam traps have become the most widespread in steam condensate systems in Russia.

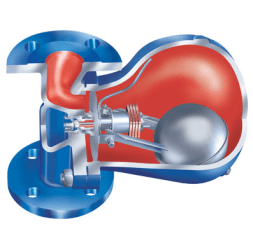

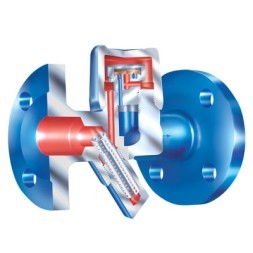

The principle of operation of thermodynamic condensate traps

The principle of operation of the devices is based on the difference in the speeds of condensate and steam, which passes between a fixed seat and a movable disk. When the condensate moves, its lower speed moves the disk to the upper position. During the passage of steam, which moves at high speed, the disk descends. A large contact area is formed and as steam condenses, the pressure above the movable disk decreases and it rises again, removing condensate.

Application of thermodynamic steam traps

The thermodynamic coupling, flange or welded condensate trap is designed for installation on main steam pipelines in heating systems, boiler rooms, thermal power plants. As a rule, the equipment is mainly used in systems with medium or high pressure. The devices are also used to drain condensate from technical tanks, disc presses, pressure reducing equipment, vulcanization systems, etc. Most models can be installed both indoors and outdoors.

Buy thermodynamic steam traps

In the company "Salutech" you can buy a thermodynamic condensate trap manufactured by ADL, CORAL, ADCA. Our online store has a large selection of models with different technical and operational characteristics. We have low prices for thermodynamic steam traps, as well as discounts and promotions. The devices are delivered to all localities. The products are guaranteed. You can order steam traps by phone or online.