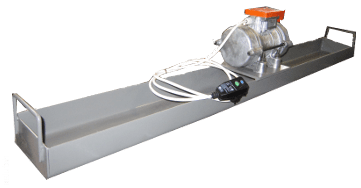

Sectional vibrators

Modular or sectional vibrating rack is a construction equipment for leveling and compacting concrete surfaces over large areas. The width of the processing strip can reach 5 meters. The equipment complies with GOST 31552-2012 and is available in two versions: with electric or gasoline drive.

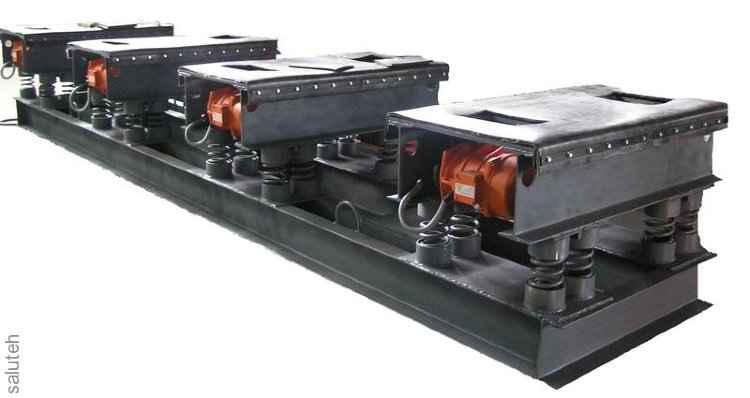

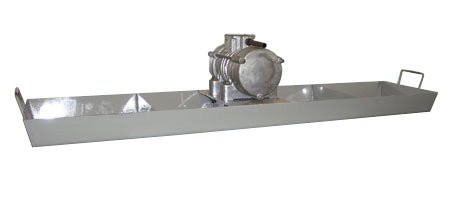

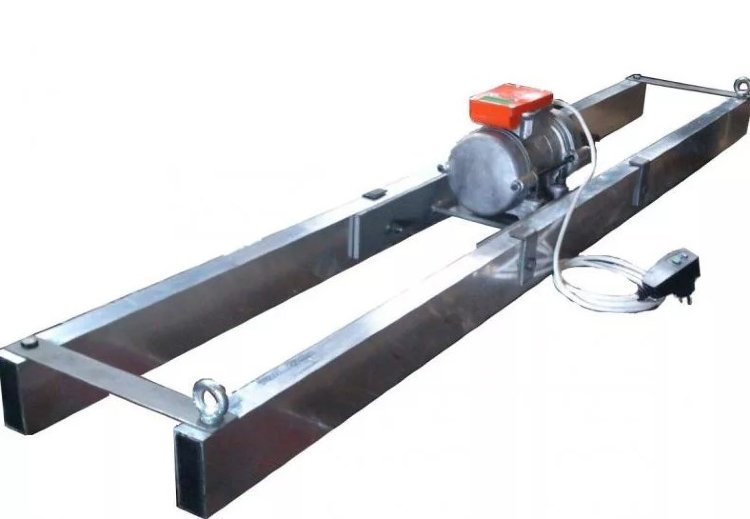

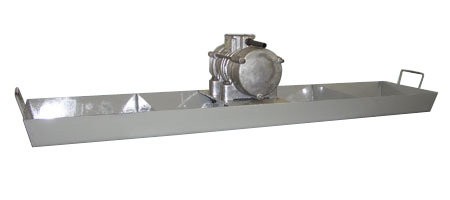

Construction of a sectional vibrating rack

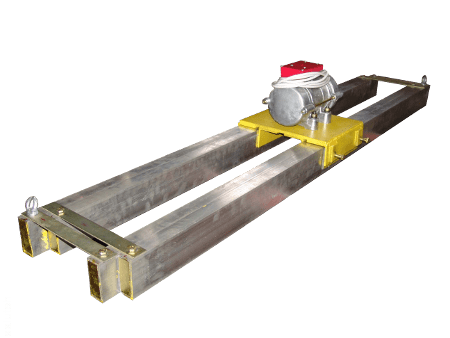

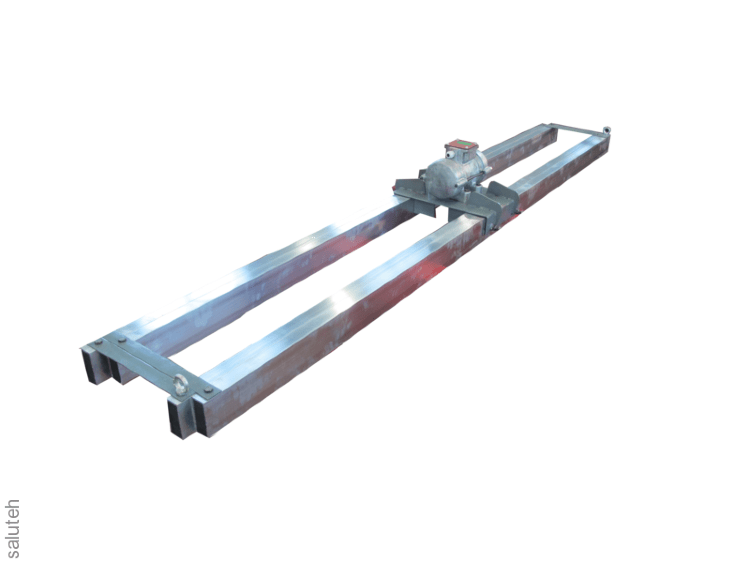

The sectional vibrating rack for concrete consists of three types of sections:

- The head is the main leveling tool mounted on the drive;

- intermediate - finishing elements with a length of 0.5-3 mm, the number of which depends on the width of the processing;

- the final part is the final part equipped with a handle or fastenings for a winch.

The electric or gasoline engine of the vibrating rack drives a shaft with eccentrics. When moving, vibration is created, which is distributed along the entire length of the tool.

Advantages of sectional vibrators

Sectional vibration rails have advantages:

- accelerate the workflow - the speed of 1 linear meter per minute;

- provide high-quality ramming;

- ensure uniform alignment;

- They are used for concrete layers up to 0.5 m deep;

- Ease of use;

- No additional equipment is required to assemble the sections;

- the ability to adjust the angle of inclination of the sections.

The scope of application of sectional vibrators

With the help of sectional vibrators, concrete is laid during the construction of roads, parking lots, playgrounds, runways, bridges and other linear and large-area objects.