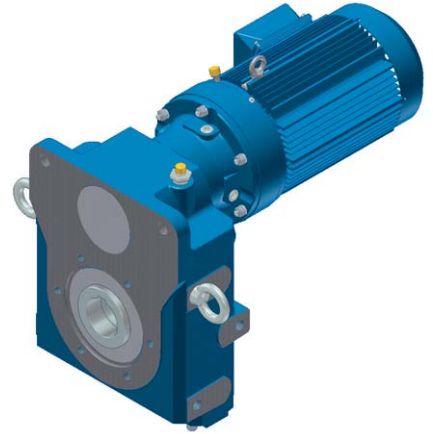

Multistage high pressure centrifugal pumps of the series LBU, LBM, LBE productions EDUR They are designed for pumping liquids in various industry directions, including slightly polluted streams. One channel, the suction nozzle is located coaxially to the motor unit, falling radially upwards, horizontal orientation of the installation. Three-phase AC electric motors with a high class of protection against dust and moisture are used as a drive in the standard version, individual settings are available on request.

Various materials and their combinations for component parts (housing, impeller) are available to choose from: cast iron, bronze, stainless steel. The shaft is made of various grades of stainless steel, sealed with a mechanical seal (single and double-sided). The LBM series is additionally equipped with a magnetic coupling that reliably separates the two functional units.

Pumping liquids: water, solutions, oils, etc.

Limitations: absence of abrasive inclusions, contact with chemically aggressive agents.

Areas of application: water purification, irrigation, boiler power, cooling systems, washing plants, filtration, marine applications and other technological processes and industries.

Technical characteristics of EDUR centrifugal pumps of the LBU, LBM, LBE series

- Volume consumption: up to 64 m3/hour;

- Discharge height: up to 350 m;

- Nominal pressure (PN): up to 25 bar (LBE up to 30 bar);

- Diameter of the suction pipe: 65 - 80 mm;

- Diameter of the pressure nozzle: 40 - 65 mm;

- Viscosity of the liquid: up to 115 mm2/sec;

- Liquid temperature: -40 to 140 °C (LBM to 180 °C).

- Installation: horizontal.

Overall standard sizes of EDUR pumps of the LBU, LBM, LBE series

LBU 401 A142L, LBU 402 A142L, LBU 403 A142L, LBU 404 A142L, LBU 405 A142L, LBU 406 A142L, LBU 407 A142L, LBU 408 A142L, LBU 409 A142L, LBU 410 A142L, LBU 401 B150L, LBU 402 B150L, LBU 403 B150L, LBU 404 B150L, LBU 405 B150L, LBU 406 B150L, LBU 407 B150L, LBU 408 B150L, LBU 401 C120L, LBU 402 C120L, LBU 403 C120L, LBU 404 C120L, LBU 405 C120L, LBU 406 C120L, LBU 407 C120L, LBU 408 C120L, LBU 409 C120L, LBU 601 C160L, LBU 602 C160L, LBU 603 C160L, LBU 604 C160L, LBU 605 C160L, LBU 606 C160L, LBU 601 D150L, LBU 602 D150L, LBU 603 D150L, LBU 604 D150L, LBU 605 D150L, LBU 606 D150L, LBU 601 D160L, LBU 602 D160L, LBU 603 D160L, LBU 604 D160L, LBU 601 E150L, LBU 602 E150L, LBU 603 E150L, LBU 604 E150L, LBU 601 E162L, LBU 602 E162L, LBU 603 E162L, LBU 601 F170L, LBU 602 F170L, LBU 603 F170L

LBE 401 A142L, LBE 402 A142L, LBE 403 A142L, LBE 404 A142L, LBE 405 A142L, LBE 406 A142L, LBE 407 A142L, LBE 408 A142L, LBE 409 A142L, LBE 410 A142L, LBE 401 B150L, LBE 402 B150L, LBE 403 B150L, LBE 404 B150L, LBE 405 B150L, LBE 406 B150L, LBE 407 B150L, LBE 408 B150L, LBE 401 C120L, LBE 402 C120L, LBE 403 C120L, LBE 404 C120L, LBE 405 C120L, LBE 406 C120L, LBE 407 C120L, LBE 408 C120L, LBE 409 C120L, LBE 601 C160L, LBE 602 C160L, LBE 603 C160L, LBE 604 C160L, LBE 605 C160L, LBE 606 C160L, LBE 601 D150L, LBE 602 D150L, LBE 603 D150L, LBE 604 D150L, LBE 605 D150L, LBE 606 D150L, LBE 601 D160L, LBE 602 D160L, LBE 603 D160L, LBE 604 D160L, LBE 601 E150L, LBE 602 E150L, LBE 603 E150L, LBE 604 E150L, LBE 601 E162L, LBE 602 E162L, LBE 603 E162L, LBE 601 F170L, LBE 602 F170L, LBE 603 F170L

LBM 401 A142L, LBM 402 A142L, LBM 403 A142L, LBM 404 A142L, LBM 405 A142L, LBM 406 A142L, LBM 407 A142L, LBM 408 A142L, LBM 409 A142L, LBM 410 A142L, LBM 401 B150L, LBM 402 B150L, LBM 403 B150L, LBM 404 B150L, LBM 405 B150L, LBM 406 B150L, LBM 407 B150L, LBM 408 B150L, LBM 401 C120L, LBM 402 C120L, LBM 403 C120L, LBM 404 C120L, LBM 405 C120L, LBM 406 C120L, LBM 407 C120L, LBM 408 C120L, LBM 409 C120L, LBM 601 C160L, LBM 602 C160L, LBM 603 C160L, LBM 604 C160L, LBM 605 C160L, LBM 606 C160L, LBM 601 D150L, LBM 602 D150L, LBM 603 D150L, LBM 604 D150L, LBM 605 D150L, LBM 606 D150L, LBM 601 D160L, LBM 602 D160L, LBM 603 D160L, LBM 604 D160L, LBM 601 E150L, LBM 602 E150L, LBM 603 E150L, LBM 604 E150L, LBM 601 E162L, LBM 602 E162L, LBM 603 E162L, LBM 601 F170L, LBM 602 F170L, LBM 603 F170L