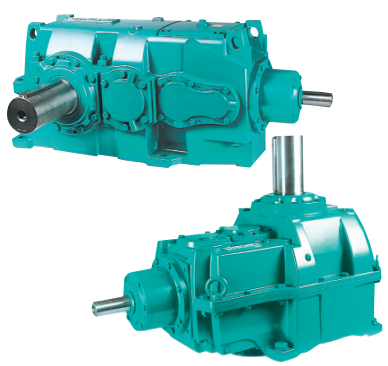

GFL suspended cylindrical gearbox, space-saving and efficient.

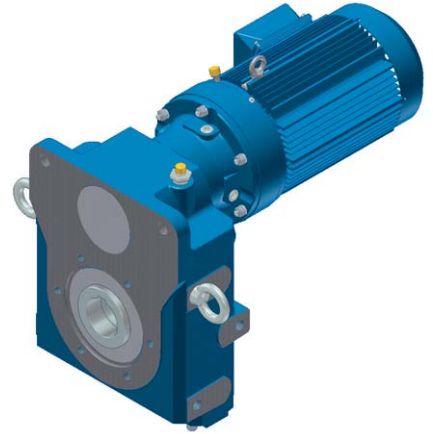

In combination with 3F AC motors and servomotors, our outboard cylindrical gearboxes are compact and efficient drive modules.

The low toothed backlash ensures maximum accuracy. In addition, they can also distribute the output power and torque by means of a drive shaft on both sides. The gearboxes are available in a 2- and 3-stage versions with a torque of up to 11.615 Nm and a gear ratio of up to i=856.

Various versions of the Drive Systems in conjunction with the decentralized Inverter drives of the 8400 motec cover a power range of up to 7.5 kW.

Our designs are for you:

- 2-speed and 3-speed gearboxes

- Hollow shaft with keyway or crimping ring

- Solid shaft with keyway

- Installation on paws or flange

- Torque plate, including rubber buffer

Lenze cylindrical flat gear motors have the following power range: from 0.12 kW to 45 Kw. A wide range of gear ratios, up to i=856, - in combination with a small step=1.12 - allows you to accurately select the required output shaft rotation frequency.

The design of all Lenze engines is based on the modular principle, which ensures the high flexibility of the proposed gear motors.

Reliability in operation is ensured by insulation class F and protection degree IP 55.

The double-coated wire winding with additional phase insulation has a high degree of protection against breakdowns, withstands high voltages and is particularly resistant to mechanical damage. To solve the widest range of complex drive tasks, this type of gear motors is perfectly combined with a frequency converter and a Lenze servo converter.

Cylindrical flat gear motors with integrated motec frequency converter are ideal for compact, decentralized drive applications.

This type of gear motor is most often used with a hollow shaft, as an output version. The high quality of the connecting elements and gears of Lenze gearboxes ensures a low (no more than 20 min.) backlash in the operation of these devices when they are used.

Versions at the entrance:

- gear motor

- servo gear motor

- gear motor with integrated frequency converter

- flange for motors with IEC standard

- free input shaft

- compact devices

Output versions:

- solid shaft

- hollow shaft

- hollow shaft with insert

- paws

- the flange

- centered threaded hole

The double-coated wire winding with additional phase insulation has a high degree of protection against breakdowns, withstands high voltages and is particularly resistant to mechanical damage. To solve the widest range of complex drive tasks, this type of gear motors is perfectly combined with a frequency converter and a Lenze servo converter.

Cylindrical flat gear motors with integrated motec frequency converter are ideal for compact, decentralized drive applications.

GFL Gearbox size Gear ratio range

04 05 06 07 09 11 14

Output torque, nm (at high gear ratio)

GFL-2 190 345 657 1337 3107 4882 11334 i=3,5 - 90

GFL-3 345 657 1378 3170 5952 11150 i=63 - 856

Description:

Gear motor GFL09-2MSDR112C32, No.16333460

Technical description:

Motor code MDEMABR112-32C0C

Motor Series Asynchronous motor

Mounting on the gearbox (flange) Direct installation (dvig. integrated.)

Estimated power 5.5 kW

Rated torque 36.6 Nm

The estimated rotation speed is 1445 rpm

Rated voltage 230 /400 V +-10%

Rated current 21.7 /12.5 A

The estimated frequency is 50 Hz

cosine ϕ (power factor) 0.77

Gear ratio 27.173

The rotation speed is output. shaft 53.2 rpm

Torque output. shaft 958 Nm

Service factor 2.37

Degree of protection IP55

Operating mode S1

Temperature class F

Cooling Built-in. fan

PTC Engine Protection

Output shaft S- shrink disc 65, pos. 1

Gearbox design D without paws, without centering

Output flange R - without flange

Terminal box Position 2

Connection type Standard

Mounting position A

Type of lubricant CLP 460

The ventilation element is installed

Anti-corrosion coating OKS-S (Small; C1)

Color RAL 7012 (grey)

Protection of the output shaft oil seal Viton

Support from turning Rubber shock absorber

Brake, execution Spring-loaded

Brake size 14

Brake voltage 24 V DC

Brake design is non-adjustable

Brake torque 60 Nm

Brake with O-ring Yes

Engine code C86 (for IF) 1257