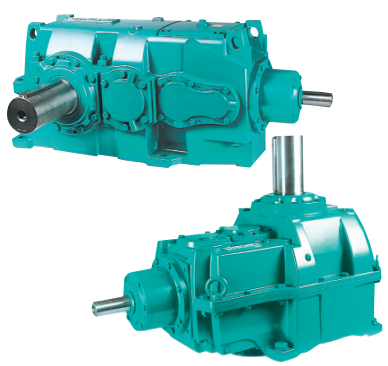

Perske Milling Engines series KNS, KRS VS, VUS This is the result of many years of experience in the field of high-speed milling, these compact and reliable models they can work with collet sizes from 2 to 25 mm. For proper positioning, there is an adjustment element located between the legs on the machine support.

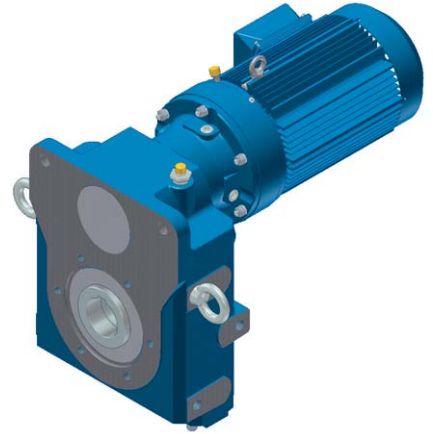

These electric motors are designed for operation Continuous operation (S1), in S6 mode - 60% performance is 20% higher. Due to the permanent lubrication of the bearings, they are easy to operate and do not require maintenance. The cooling system is represented by an integrated fan located on the motor shaft, the features of its design make it possible to reduce the noise level (the only modification without ventilated cooling SUVs has the lowest sound level).

There are single and double supports (D) models, in the standard version, the direction of rotation is to the right, left-hand on request. Also on sale is version with hydraulic clamping chucks (KRSV), with simple controls, for left- and right-hand rotation.

Technical characteristics of milling motors Perske KNS, KRS VS, VUS:

- Rated power: 0.15 – 12 kW;

- Operating speed range: 9000 - 30,000 rpm;

- Overall height: 35 - 75 mm;

- The degree of protection of the case: IP54;

- Degree of protection: self-ventilation;

- Insulation class: F

Standard sizes motor for Perske milling machines

| Engine Type | Power, kW | |||||

| 9000 rpm | 12000 rpm | 18000 rpm | 24000 rpm | 30,000 rpm | Max. clamp, mm | |

| KNS 21.05-2 | 0.15 | 0.2 | 0.32 | 0.4 | 0.4 | 13 |

| KNS 22.08-2 | 0.24 | 0.32 | 0.5 | 0.6 | 0.6 | 13 |

| KNS 23.10-2 | 0.3 | 0.4 | 0.6 | 0.7 | - | 13 |

| VS 30.06-2 | 0.3 | 0.42 | 0.6 | 0.65 | 0.65 | 13 |

| VS 31.09-2 | 0.45 | 0.65 | 0.9 | 1.0 | 1.0 | 13 |

| VS 50.09-2 | 1.5 | 1.85 | 2.5 | 3.0 | 3.0 | 16 |

| VS 60.11-2 | 3.0 | 4.0 | 5.0 | 5.0 | 5.0 | 16 |

| VS 61.15-2 | 4.0 | 5.0 | - | - | - | 16 |

| SUV 50.09-2 | 0.55 | 0.8 | 1.0 | 1.0 | 16 | |

| SUV 60.11-2 | 1.9 | 2.1 | 2.6 | 2.6 | 16 | |

| SUV 61.15-2 | 2.6 | 2.8 | - | - | 16 | |

| KRS 35.1-2 D | 0.5 | 0.7 | 0.9 | 1.0 | 13 | |

| KRS 35.3-2 D | 0.7 | 1.0 | 1.3 | 1.4 | 13 | |

| KRS 35.5-2 D | 1.0 | 1.4 | 1.9 | 2.0 | 13 | |

| KRS 35.7-2 D | 1.1 | 1.6 | 2.2 | - | 13 | |

| KRS 35.9-2 D | 1.4 | 2.0 | - | - | 13 | |

| KRS 50.11-2 D | 2.5 | 3.0 | 4.0 | 16 | ||

| KRS 51.14-2 D | 3.5 | 4.0 | 5.0 | 16 | ||

| KRS 52.16-2 D | 4.0 | 4.5 | - | 16 | ||

| KRSV 51.14-2 D | 3.5 | 4.0 | 5.0 | 25 | ||

| KRSV 51.14-2 D | 3.5 | 4.0 | 5.0 | 25 | ||

| KRS 60.09-2 D | 3.0 | 3.5 | - | 20 | ||

| KRS 61.13-2 D | 5.0 | 6.0 | 7.0 | 20 | ||

| KRS 62.18-2 D | 6.0 | 7.0 | - | 20 | ||

| KRS 60.09-2 D | 3.0 | 3.5 | - | 25 | ||

| KRS 61.13-2 D | 5.0 | 6.0 | 7.0 | 25 | ||

| KRS 62.18-2 D | 6.0 | 7.0 | - | 25 | ||

| KRSV 61.13-2 D | 5.0 | 6.0 | 7.0 | 25 | ||

| KNOCS 71.16-2 D | 7.0 | 8.0 | 10.0 | 20 | ||

| KNOS 71.16-2 D | 7.0 | 8.0 | 10.0 | 25 | ||

| KNOCS 71.20-2 D | 9.0 | 10.0 | 12.0 | 20 | ||

| KNOS 71.20-2 D | 9.0 | 10.0 | 12.0 | 25 |