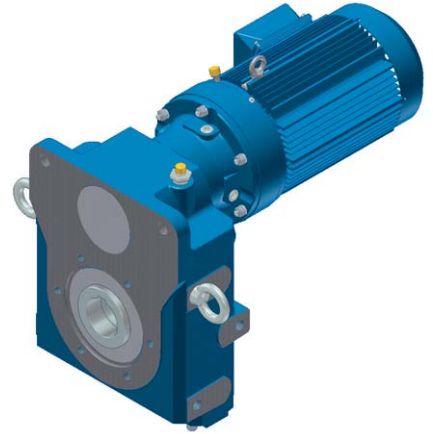

Pressure transmitter PMP51-J450/0 Cerabar M PMP51 PMP51-AA12QA1HGBGXJA3

Absolute and overpressure converter Cerabar PMP51

Digital pressure transducer with welded metal membrane for measurements in gases, vapors and liquids

The Cerabar PMP51 digital pressure transmitter with a metal membrane is used in any industry to measure pressure, level, volume and mass in liquids. The PMP51 is designed to meet the challenges of measuring high pressure up to 400 bar.The quick setup menu with adjustable measuring range provides easy commissioning, reduces costs and saves time. SIL2 in accordance with GOST R IEC 61508 and GOST R IEC 61511 (IEC 61508 and IEC 61511).

Advantages:

- Accurate measurement of process parameters even at varying process temperatures

- Process safety due to the small flush connection to the process for hygienic applications

- For monitoring process pressure in systems up to SIL2, certified according to IEC 61508 and IEC 61511 (GOST R IEC 61508 and GOST R IEC 61511)

- Modular concept for easy replacement of the display and electronics unit

- Simple menu-based commissioning via local display, 4 ... 20 mA using HART protocol, PROFIBUS PA, FOUNDATION Fieldbus

- Simple and independent system integration (HART/PA/FF)

Scope of application

- Single-chamber housing made of aluminum or stainless steel (316L).

- Process connections: threaded, flanged or hygienic connections

- Process temperature: -40 ... +130°C, 150°C max. for 1 hour.

- Measuring range: -1/0 mbar...+400 bar

- Basic error: ±0.15%, "Platinum" ±0.075%

- International explosion protection certificates, overflow protection WHG, SIL, hygiene certificates, marine certificates

Application

Continuous measurement/liquid products

Measurement principle Absolute and overpressure

Specifications

- Intelligent pressure transducer, with strain-resistant sensing element and welded metal measuring diaphragms

- Supply voltage 4...20 mA HART

- 11.5...45 Per post. current (version for safe zones):

- Ex ia: 11,5...30 In the post. current

- PROFIBUS PA: 9...32 Per post. current (version for safe zones)

- FOUNDATION Fieldbus: 9...32 Per post. current (version for safe zones)

- The error is 0.15%

- Platinum 0.075 calibration%

Long-term stability

- < 0,1% ВПИ/год

- 0.2% VPI/5 years

- 0.25% VPI/10 years

The operating temperature is -40°C...125°C

Ambient temperature -40°C...85°C

The operating range is 400 mbar...400 bar

(15...6000 lb/sq. inch)

rel./abs.

- The smallest calibrated scale pitch is 20 mbar (2.9 lb/sq. inch) rel./abs.

- The vacuum resistance is 10 mbar (1.45 lb/sq. inch) abs

- Max. the width of the reconfiguration of the measuring range is 20:1

- Max. overpressure 600bar

- Joining the process Threaded

- Flanged (DIN, ANSI, JIS)

Hygienic connection to the Tri-Clamp process

- DIN11851

- NEUMO

- Varivent N

- SMS

- DRD

The membrane material of the process is 316L, alloy AlloyC, Tantalum, Rhodium>Gold

Gasket material No, welded measuring module

Filling liquid: Silicone oil, Inert Oil

Body material Cast aluminum, AISI 316L

Communication 4...20 mA HART, PROFIBUS PA, FOUNDATION Fieldbus

ATEX, FM, CSA, CSA C /us, IEC ex, tiis, INMETRO, NEPSI

Safety certificates SIL

Design certificates EN10204-3.1, NACE MR0175

Hygiene certificates 3A, EHEDG, CoC ASME-BPE

Marine certificate GL/ABS/LR/BV/DNV

NSF Drinking Water Certificates