The main technical parameters of gearboxes

ieff - the gear ratio, is an indicator of the ratio of the input and output power of the gearbox, indicates how many times the torque of force will increase after reduction. T2 (Nm) is the torque value on the output shaft of the gearbox, with an operating time of 10,000 hours, in accordance with I.S.O. (D.P. 6336), is given for linear and rectangular versions depending on the input speed.

T2MAX (Nm) - the value of the maximum torque, the permissible peak load values for short periods of time in conditions of constant load or variable, in conditions of frequent starts, reversals.

TN (Nm) - rated torque, the limit value for safe operation, characterizing each gearbox size, in accordance with I.S.O. (P.D. 6336)

P2 (kW) - rated power, calculated with an operating time of 10,000 hours

PT (kW) - the power transmitted continuously by the gearbox in operating conditions that advise the maximum permissible temperature loads

n1 (rpm) - speed at the entrance

KA - the factor of application conditions (service factor), an experimental indicator that reflects the operating conditions, takes into account variations in load, transmission and uncertainty about changes in parameters associated with power transmission, the duration of operation per day, start/stop mode per hour of operation. You need to multiply it by the rated torque (or power) to get the reference torque (or power), which will be compared with the catalog value.

Selection of gearboxes for various industries, recommended values of the service factor (KA)

| Scope of application | KA |

| Stirrers | |

| clean liquids | 1 |

| liquids with impurities of solid particles | 1,25 |

| liquids of variable density | 1,25 |

| Machines for working with clay | |

| brick | 1,75 |

| pressing machine | 1,75 |

| clay grinder | 2 |

| Conveyors | |

| worm conveyor | 1 |

| with uniform loading or feeding | 1 |

| uneven feed | 1,25 |

| scraper or vibrating conveyor | 1,75 |

| Dry dock cranes | |

| main winch | 2,5 |

| auxiliary winch | 2,5 |

| arrow, departure | 2,5 |

| rotary | 2,5 |

| running and driving wheels | 3 |

| Container Gantry Cranes | |

| main winch | 3 |

| arrow, departure | 2 |

| Cranes | |

| main winch | 2,5 |

| auxiliary winch | 2,5 |

| running gear of the bridge | 3 |

| undercarriage of the trolley | 3 |

| Crushers | |

| Stone or ore | 1,75 |

| Draghi | |

| with rope drums | 1,25 |

| conveyor belts | 1,25 |

| cutter drives | 2 |

| screen drives | 1,75 |

| stackers | 1,25 |

| winches | 1,25 |

| Lifts | |

| bucket | 1,25 |

| escalators | 1 |

| Extruders | |

| general | 1,5 |

| plastic recycling | |

| with variable speed | 1,5 |

| at a constant speed | 1,75 |

| rubber extrusion | |

| continuous operation | 1,75 |

| with breaks | 1,75 |

| Feeders | |

| lamellar | 1,25 |

| ribbon | 1,25 |

| screw | 1,25 |

| Food industry | |

| grain razvarniks | 1 |

| dough mixers | 1,25 |

| meat grinders | 1,25 |

| Winches | |

| heavy duty | 1,75 |

| medium mode | 1,25 |

| skip winch | 1,25 |

| Laundries | |

| drums | 1,25 |

| washing machines | 1,5 |

| Forestry industry | |

| burner conveyor | 1,25 |

| continuous load | 1,5 |

| processing of trunks | 1,75 |

| planing machines | 1,75 |

| loading elevator | 1,25 |

| the picker's drum | 1,75 |

| milling cutter | 1,25 |

| chain transmission | 1,5 |

| Mills and related metalworking equipment | |

| reversible rolling mill | 2 |

| sheet metal rental | 1,5 |

| metal cutting | 2 |

| wire drawing | 1,25 |

| winding the wire | 1,5 |

| Machines for processing metal products | |

| belt-pulling mechanism | 1,25 |

| unwinding /reeling machines | 1 |

| milling machines | 1,25 |

| the right cars | 1,25 |

| pressure shafts | 1,25 |

| recycling of scrap metal | 1,25 |

| metal cutting shears | 2 |

| longitudinal cutting | 1,25 |

| Cement industry | |

| cement kilns | 1,5 |

| dryers and coolers | 1,5 |

| concrete mixers | 1,25 |

| Paper industry | |

| agitators (mixers) | 1,5 |

| agitators (liquids) | 1,25 |

| calenders | 1,25 |

| crushing plants | 2 |

| crusher loader | 1,5 |

| roller coating | 1,25 |

| conveyors for wood chips and bark | 1,25 |

| conveyors for logs | 2 |

| paper making machine | 1,25 |

| conveyors | 1,5 |

| hot pressing | 1,5 |

| sorting of wood chips | 1,5 |

| rotary sorters | 1,5 |

| vibrating sorters | 2 |

| The press | 1,25 |

| super-calenders | 1,25 |

| thickeners (AC motor) | 1,5 |

| thickeners (DC motor) | 1,25 |

| washers (AC motor) | 1,5 |

| washers (DC motor) | 1,25 |

| The plastic industry | |

| batch mixers | 1,75 |

| mixers with continuous operation | 1,5 |

| calenders | 1,5 |

| Rubber production | |

| batch mixers | 1,75 |

| mixers with continuous operation | 1,5 |

| calenders | 1,5 |

| forming | 1,25 |

| Wastewater treatment | |

| rod gratings | |

| chemical feeders | 1,25 |

| dewatering augers | 1,5 |

| settling tanks | 1,5 |

| slow and fast stirrers | 1,5 |

| sediment collectors | 1,25 |

| thickeners | 1,5 |

| vacuum filters | 1,5 |

| air washing strainers | 1 |

| rotary - stone or gravel filter | 1,25 |

| Sugar industry | |

| beetroot cutters | 2 |

| reed cutters | 1,5 |

| shredders | 1,5 |

| mills (low speed) | 1,75 |

| Textile industry | |

| dispensers | 1,25 |

| calenders | 1,25 |

| dryers | 1,25 |

Auxiliary technical parameters for the selection of the gearbox

Cs - a factor that takes into account the number of launches per unit of time.

| The factor | Number of launches per hour | |||

| 1-5 | 6-25 | 26-100 | 101-200 | |

| Cs | 1 | 1,05 | 1,15 | 1,25 |

Temperature (°C)

The optimal temperature regime for the gearbox operation is in the range from 50 ° C to 70 ° C, an increase to 80 ° C is permissible with short-term exposure. It is recommended to use auxiliary cooling systems to maintain the benchmarks in this operating range. At lower ambient temperatures (below -15 °C) or for conditions above 80 ° C, special lubricants must be used.

Load on the input and output shafts FR (N)

The diagram below gives the values of permissible radial loads on the output shaft, an example of a bearing n2 x h=105 is indicated. For different duration of exposure, the obtained value should be multiplied by the coefficient C (Diagram 2), which should not exceed 1.5.

Calculation example:

Gearbox size SL3003 MPRadial load F=185 000 N

Position X=- 50 mm

Output shaft rotation speed n2=20 rpm

We determine the radial load according to diagram 1:

FR=150000 N

We calculate the coefficient:

C=F/FR=185000 /150000=1.23

1,23 < 1,5 (C max)

Bearing service life:

n2 * h=0.5 * 105 (according to Diagram 2)

h=0,5 * 105 /20=2500 (h)

Hollow shaft gearboxes are not suitable for radial load support and are only used for torque transmission.

To calculate the axial load, it is necessary to contact our engineers to provide control data.

Thermal power PT (kW)

This indicator reflects the ability of the gearbox to dissipate heat, exceeding the permissible values of this indicator can lead to failure or breakdown of the device as a result of loss of the working properties of lubricants. The correction values of the coefficients for this indicator are presented below.

The K-factor

This correction factor is used for cyclic operation and/or in ambient temperatures other than 20 °C.

| Number of hours work per day | Ambient temperature (°C) | ||||

| 10° | 20° | 30° | 40° | 50° | |

| ≥10 | 1,15 | 1 | 0,85 | 0,7 | 0,6 |

| 8 | 1,25 | 1,1 | 1 | 0,85 | 0,7 |

| 6 | 1,4 | 1,25 | 1,1 | 1 | 0,85 |

| 4 | 1,6 | 1,4 | 1,25 | 1.1 | 1 |

| 2 | 1,8 | 1,6 | 1,4 | 1,25 | 1,1 |

The S-factor

If the input speed is different from 1500 rpm, the thermal load can be adjusted using the S coefficient.

| Ratio | Number of rpm | |||

| 1750 | 1500 | 1000 | 500 | |

| S | 0,94 | 1 | 1,05 | 1,1 |

The R-factor

If the transmission is located in a confined space or outdoors, the thermal power can be adjusted using the R factor.

| Ratio | A small room | A large room | street |

| R | 0,70 | 1,00 | 1,35 |

Thus, the calculation of the thermal power of the gearbox, taking into account the above factors of influence, will be as follows:

PT1=PT * K * S * R

The thermal power must be higher than the power transmitted to the transmission in all operating modes. If the thermal power of the gearbox is less than the transmitted power, even in one condition of a possible operating cycle, an auxiliary cooling circuit must be provided.

Example of gear selection

Initial data:

Engine: electric, power 22 kW, rotation speed 1500 rpmEquipment:

Conveyor belt, uneven loading

Operating mode: continuously 10 hours a day, the number of launches per hour is 1

Required operating torque: 100000 Nm

Maximum torque on the star: 200,000 Nm

Rotation speed: 1.9 rpm

Required service life: 10000 hours

Working position: horizontal

Ambient temperature 30 ° C

Workplace: large room

Gear selection:

Required ratio: 1500 /1.9=789Application coefficient KA: 1,25

Torque for gear selection:

T2=100000 • KA * Cs=100000 • 1.25 • 1=125000 ②

The selected gearbox must have a control torque T2> T2R when choosing.

Select the T value in the catalogN not exceeding the received value (T2R=125000), that is, 133000 Nm, in the same row of the "Type" column it is indicated that the gearbox has a dimension of S1200. In the "Technical data" table, select the value "ieff", which is closest to the requested i=789, in our case ieff will be 778.1. Then from the column corresponding to 1500 rpm, in accordance with the selected ratio, you will read T2=133173 Nm: therefore, the correct gearbox will have the "SL12004" configuration.

Maximum torque of the gearbox SL12004 T2max=250,000 Nm>200,000 Nm

Thermal power of the gearbox SL12004 PT=31 kW

We take into account the factor of ambient temperature K:

PT1=31 • 0.85=26.35 kW

Since the input speed is 1500 rpm, the coefficient S=1

The power required by the application: 100000 • 1,9 /9550=20 kW

Thus, considering that the condition 26.35 kW>20 kW is fulfilled, an auxiliary cooling system of the gearbox is not required.

Applications that:

- they require duration values other than 10000 hours

- they have different input speeds from the values specified in the catalog

- they are characterized by operating cycles with variable speeds and loads

- they provide for the presence of axial loads at the input /output of the gearbox

They must be considered separately, using special calculation programs, for this, contact our specialists for help.

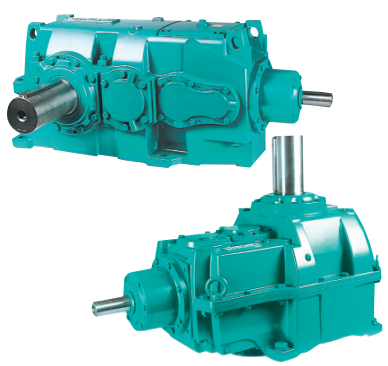

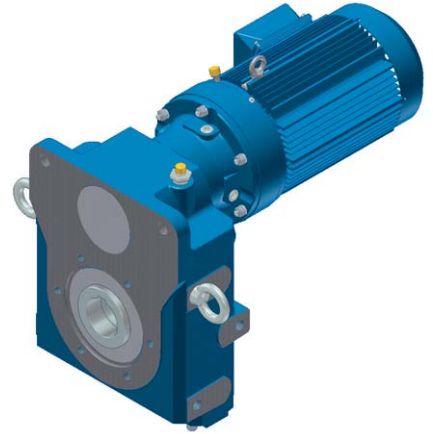

Our company provides a wide range of gearboxes of European brands Brevini, DANA, PIV Drives, individual approach to each client, engineering support and selection of optimal technological solutions for the implementation of your production project.