VEGAMIP R61 MPR61.GXAGA1RAMX Damage Detector

Microwave radiation by its nature penetrates through non-metallic materials and substances. Due to this, microwave level sensors of bulk materials function reliably in conditions of high dust, fog, rain and snow. The microwave alarm of the maximum level of bulk materials is not sensitive to sticking and deposition of the controlled material on the sensitive surfaces of the sensor. This advantage allows the use of sensors instead of optical barriers, where the solution of the problem is complicated by difficult environmental conditions.

The microwave level sensor cuts into the walls of metal bunkers and pipelines. If the material of the walls of the container or product line is non-metallic, it is not necessary to embed the microwave level sensor into the wall. A microwave limit level detector can be installed outside a bunker or silo if its walls are made of concrete, brick, glass block or plastic. The microwave level detector can be easily separated from the controlled process using a mortise window made of ceramics, quartz glass, fluoroplast and other non-conductive materials. When the microwave detector is installed outdoors, the detection distance decreases, depending on the wall material.

The power of microwave radiation does not exceed 10 MW, which is absolutely harmless to personnel, unlike radiation from radioisotope level detectors. The cost of microwave level detectors is much lower than radioisotope ones, which is another argument in favor of the former.

Microwave level detectors are an ideal solution for monitoring the bulking of overload leaks in conveyor transport systems.

The distance between the receiver and the transmitter (emitter) of the microwave level detector can reach 200 meters. Microwave level detectors are used as level detectors for bulk materials in the construction industry, the mining and processing industry, and the extractive industry. A microwave limit level detector can also be used to control the level of liquids and melts, for example in the metallurgical industry. Microwave alarms are widely used as position sensors for vehicles, large-sized objects, hot objects in the pipe rolling industry, mining and processing industries.

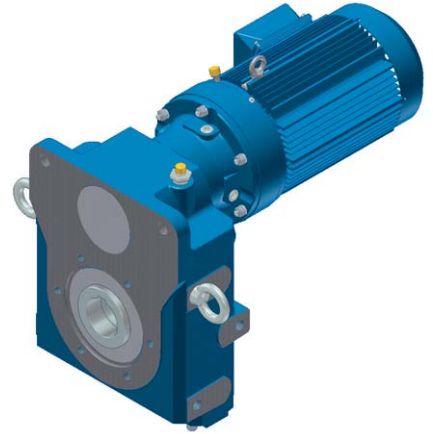

VEGAMIP 61 is a microwave barrier transmission unit designed to signal the limit level of bulk products and liquids. A typical application is to control the level of bulk products in silos, bunkers and crushers, liquids in pipelines and containers, as well as to control the position of various objects. The non-contact principle of operation provides the possibility of long-term operation without wear and maintenance.

Features

- Non-contact measurement

- Independence from product properties

- Operational reliability, including on highly abrasive products

- Measurement through the wall on plastic containers

- Technical data

- Measuring range: up to 100 m

- Joining: thread G1½, 1½ NPT, flanges, clamp

- Process temperature: -40 ... +80°C (+450°C with mounting adapter)

- Process pressure: -1 ... +4 bar (-100 ... +400 kPa)