Pressure reducing valve 701 ARI-Predu PN16 body: grey cast iron Tmax=+300oC Pcr=0.8 - 2.5bar flanged

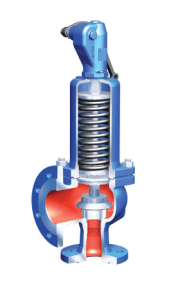

Description:

The pressure reducing valve is an automatic proportional direct acting regulator that lowers the high inlet pressure to a lower outlet pressure. The valve regulates the pressure after itself: this means that the valve closes when the outlet pressure increases.

Short description

Pressure reducing valve, nominal diameter: DN15 - DN100, nominal pressure: PN16 - PN40, operating temperature: -60C ... +450C, housing material: grey cast iron, ductile iron, cast steel

- Diameter Dn: 15-100 mm

- Rp pressure: 16/25/40 bar

- Media: water vapor, neutral gases, vapors, liquids, etc.

- Temperature: -60°C to 450°C

Materials:

- Body: cast iron EN-JL 1040 (standard), high-strength cast iron EN-JS1049, cast steel 1.0619+N

- Seat, gate, guide sleeve: n/A steel 1.4021.05

- Spring: high temperature steel 1.8159

- Sealing and balancing bellows: austentic n/W steel 1.4571

- Membrane: NBR or EPDM nitrile

- Seal: gasket - made of pure graphite with a layer of chrome-nickel steel; ring - NBR /EPDM

- Connection: flanged

- Drives: diaphragm drive DMA 40-400

Specifications

- Nominal pressure: 16/25/40

- Housing material: grey cast iron, ductile iron, cast steel

- Temperature: -60 to +450 C

- Standard Sizes (DN): DN15-DN150

- Connections: flanged

Applications – regulation of steam pressure, neutral gases, vapors and liquids. In the case of steam and liquids with temperatures exceeding the permissible operating temperatures, a condensate tank must be installed in the control line (to protect the drive membrane).

The ARI-PREDU pressure reducing valve is a proportional regulator with direct control for adjusting the pressure of liquid, gaseous and vaporous media of Group II in accordance with the Directive "Pressure equipment" 97/23/EC. Auxiliary energy is not required.

If there is no pressure, the valve is fully open. From the entrance, the medium passes through the building to the exit. The pressure behind the valve is sampled at a minimum distance of ten diameters or at a minimum distance of 1 m and supplied to the actuator via the control line.

If the temperature of the media exceeds the maximum permissible temperature of the drive, an intermediate connection of the receiving vessel is necessary. In this case, the entire area of the receiving vessel, the control lines and the drive must be filled with liquid (when working with steam – water).

With the help of the drive diaphragm, the pressure is converted into a force acting in the direction of lifting the cone. The force of the tensioned spring passes through the transverse pin and coupling into the spindle and is directed against the force of the membrane, i.e. in the direction of downward movement of the cone.

If both forces are equal, the system is in equilibrium and the (reduced) outlet pressure set on the control plate is adjusted.When the reduced pressure changes, the cone moves up or down, respectively. https://armamir.by/index.pl?act=PRODUCT&id=68

The ARI-PREDU pressure reducing valve is designed to operate as a direct-acting proportional regulator, without an auxiliary power source, to lower and regulate high inlet pressure to a lower outlet pressure. The pressure is adjusted after the valve, i.e. the valve closes when the pressure increases. When the ARI-PREDU pressure reducing valve is operating with steam and liquids with temperatures above the permissible temperature, it is necessary to put in a condensate container.

Design features of direct-acting pressure reducing valves ARI-Predu 701:

- Compactness;

- Simple and precise adjustment;

- Operating ranges;

- 5 interchangeable drive sizes;

- 3 interchangeable spring sizes;

- Pressure relief with a stainless steel bellows;

- Sealing of the gate along the conical edge of the seat;

- Threaded seat ring;

- Construction without support posts;

- Easy replacement of the spring and drive;