Level sensors

Level sensors - measuring the level of liquids and solids!

Level sensors are a necessary tool and meter in a wide variety of production areas. Level sensors are used in almost all areas of industry related to products that have a loose or liquid state. The tasks of measuring the level of liquid and dry substances in modern process automation systems are always relevant.

Types of sensors and measurement principles

To measure liquid media, the following methods are used: ultrasonic, laser, radar, capacitive,

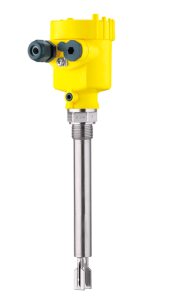

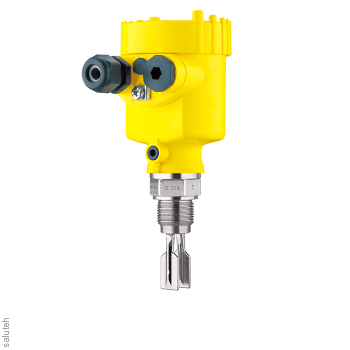

vibrating and microwave-based sensors.

Electromechanical, ultrasonic, capacitive, laser, and radar level sensors are offered for measuring bulk media.

The type of measurement and the physical principle of measurement:

| Capacitive | The change in the dielectric constant between the electrodes. |

| Membrane | Measurement of the hydrostatic pressure at the bottom of the tank. |

| Differential pressure | Measurement of the pressure difference in the lower and upper parts of the tank above the liquid level. |

| Float | The float with a permanent magnet moves along with the liquid level through the sliding pipe, which contains sealed magnetically controlled contacts. |

| Laser | Measurement of the time interval between the emitted and reflected light pulse. |

| Magnetic level gauge | The float with the magnet moves up and down the inside of the non-magnetic tube, the magnetic elements attached from the outside in the glass tube turn over with a colored face when the magnet reaches their level. |

| Microwave | High-frequency microwave pulses they are guided along a steel cable or rod. Upon reaching the surface of the product, microwave pulses are reflected from it. Based on the pulse travel time, the distance value is calculated. |

| Radar | As a result of the interaction of the radiated and reflected signals, a signal of a difference frequency arises proportional to the distance from the antenna of the emitter to the surface of the product. |

| Radioisotope | The action is based on the absorption of gamma rays when passing through a layer of matter. |

| Vibrating | The blades of the level indicator, experiencing piezoelectric action, vibrate at a mechanical resonant frequency. The attenuation of vibrations (amplitude change), which occurs due to the coating of the sensor blades with material, generates a signal. |

| Ultrasonic | It is based on measuring the time of passage of an ultrasound pulse from the radiator to the surface of the liquid and back. |

Sensors of various types for contact and non-contact measurement of tank filling levels are used both for measuring chemically aggressive media and in the food industry.

Salutech will help you select the necessary equipment!