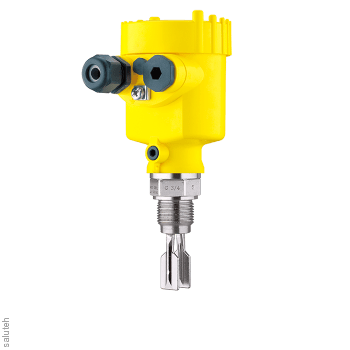

Vibration level sensors

The main applications of vibration sensors

The capabilities of tuning fork-type level sensors allow the device to be used in various industries. The use of vibration sensors in the agricultural industry, in food production, and in the field of oil refining is obvious. However, vibration level sensors are suitable for use in almost any industry where liquid and bulk product monitoring is required, not limited to the examples given.

Advantages of vibration level meters

The main advantages of vibration level meters are:

- the absence of moving parts that can jam or fail during operation significantly reduces the risk of an emergency equipment failure.

- The varying frequency of vibration vibrations makes it possible to identify not only the achievement of the maximum and minimum level of the medium in the tank, but also the deposits formed on the sensor, its mechanical damage, internal damage to the electric piezo crystal and the level of corrosion.

- The measuring system is universal. The level gauge sensor is resistant to physical and chemical properties of liquids, suspensions, creams and bulk materials.

- Compactness, and autonomy. Their operation does not require external signal processing, most vibration sensors have a built-in electronics unit that processes the received level signals and converts them into an appropriate output signal.

- The vibration level meter is capable of operating even in conditions in which other level meters cannot operate.

Where to purchase vibration level sensors

On the SALUTECH company's website, you can buy industrial level gauges, level detectors, vibration, capacitive and radar sensors. All devices are certified and supplied from the best manufacturers.