Bimetallic steam traps

The removal of the resulting condensate is an important task that arises during the operation of various pipeline systems. For these purposes, special mechanisms are used to discharge the emerging liquid in a timely manner. Bimetallic condensate drains are one of the varieties of such devices.

Purpose of bimetallic condensate drains

This equipment makes it possible to deal quite effectively with the appearance of excess liquid medium in systems, preventing breakthroughs, water shocks, reduction of thermal capacities and other unpleasant consequences. Bimetallic condensate drains are found both in industrial pipelines and in heating and water supply systems.

The main difference between this device and other options is that a bimetallic plate performs the function of a locking element in it. It is made of two different metals with different coefficients of thermal expansion. Based on the vapor saturation curve, these bimetallic elements discharge condensate. In addition, they help to remove air masses from the system, thereby preventing water strikes.

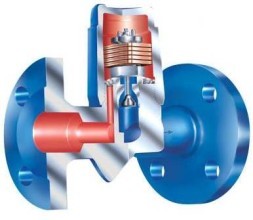

The design and principle of operation of bimetallic condensate traps

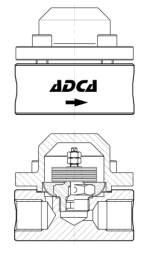

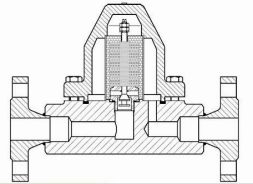

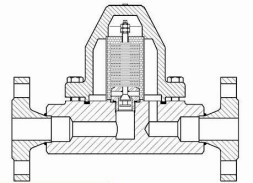

A standard steam trap consists of:

- Enclosures,

- Covers,

- Closure,

- Package of bimetallic plates,

- The shutter stem,

- Shutter seats,

- Filter plugs,

- A mesh filter.

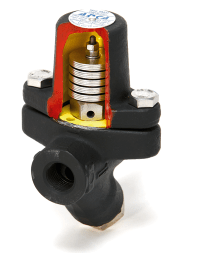

The principle of operation of the condensate trap in question is based on the properties of thermoelasticity of bimetallic washers. The working part consists of 2 plates, which are made of metal with different coefficient of thermal expansion. The lower plate has a lower coefficient of expansion than the upper one. During heating, they bend in directions opposite to each other. The heating temperature indicators have a direct proportional effect on the amount of deformation.

The shutter stem consists of a package of bimetallic washers assembled in pairs. They just lie at rest, the shutter is closed. Condensate and air entering the condensate trap are discharged under the influence of a pressure drop between the condensate and steam networks. During heating from hot condensate, the bimetallic plates bend and the working package expands. If the temperature increases only by a couple of degrees compared to the saturation temperature, then the gate is pressed against the seat (under the action of bimetal plates), thereby blocking the flow from the condensate trap.

In the closed position, the shutter is affected by the force created by the pressure of the system trying to close it. To keep the shutter in the closed position, the bimetallic bag must have sufficient closing force. With the cooling of the condensate, the forces affecting the closure of the shutter also decrease. After reaching the set temperature, the pressure increases and the shutter opens.

Advantages of bimetallic steam traps

The key advantages of these types of devices include the following factors:

- Unpretentiousness in maintenance,

- Reliability,

- Reliability,

- The ability to cope with different environments in a fairly wide temperature range, even under high pressure conditions,

- Durability,

- A wide range of standard sizes and modifications,

- Easy installation (can be performed in any position).

Scope of application of bimetallic steam traps

Modern bimetallic condensate drains can be used in the construction of:

- Various steam equipment,

- High temperature pipelines,

- Steam distribution lines.

Buy bimetallic condensate drains in Moscow

The Salutech company offers to purchase bimetallic condensate drains at a favorable price. The catalog presents various models of bimetallic condensate drains. All products are of high quality and reliability. A long-term warranty is provided.