Equipment of steam condensate systems

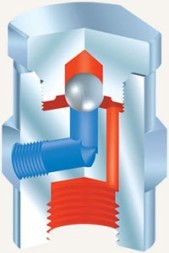

Steam condensate systems are a special set of equipment designed to collect and then return condensate that appears during cooling and the transition of steam from a gaseous state to a liquid state.

Steam condensate systems - the principle of operation

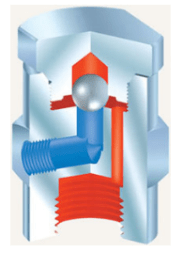

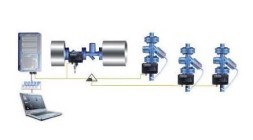

With the help of the energy transferred to the production process, the steam begins to condense, after which it enters a specialized container. Then, due to pumps, the condensate enters the dearer, where gaseous impurities are directly separated. If the steam is contaminated with various mechanical additives, certain filtration and settling measures are carried out. The condensate pressure is increased to the extent that it does not exceed the operating pressure level of the boiler, where it is transmitted back through the wires using pumps.

Advantages of steam condensate systems

The unique properties of steam as a coolant make condensate systems indispensable in various fields and have the following advantages

- Low costs for the production and operation of the system

- The practicality of the device of the basic parts of the system, which does not require a lot of resources to maintain its functioning

- Safety when using hazardous flammable materials and environmental friendliness

Applications of steam condensate systems

Steam condensate systems are widely used in circulating water supply systems and in the operation of steam generating equipment, as well as in such industries as petrochemical, metallurgical, pharmaceutical, food and light industries.

Purchase equipment for the steam condensate system

The Salutech company has in its assortment a wide range of equipment for steam condensate systems of various types. All products are certified and have an official warranty from the manufacturer of the product. Our specialists will always be able to help you choose the necessary products and will be happy to answer your questions.