Valve actuators

Valve actuators for better controllability all systems

Actuators for valves, as well as other shut-off and control valves, are, as a rule, actuators that move the shut-off organs inside the shut-off unit relative to the seat from the closed position to the open position and vice versa. The control system is used to supply a remote or local control signal to the actuator (drive) to install the locking device in the open or closed position.

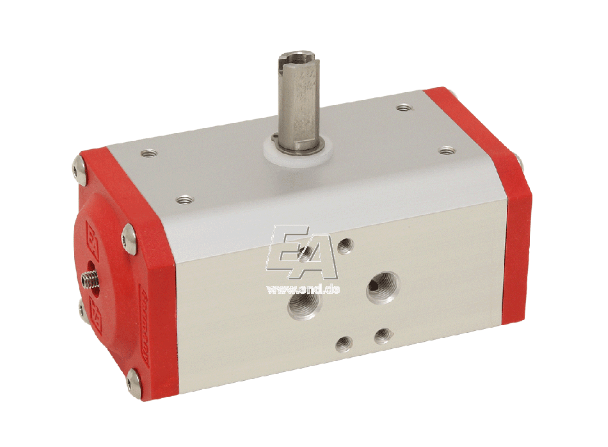

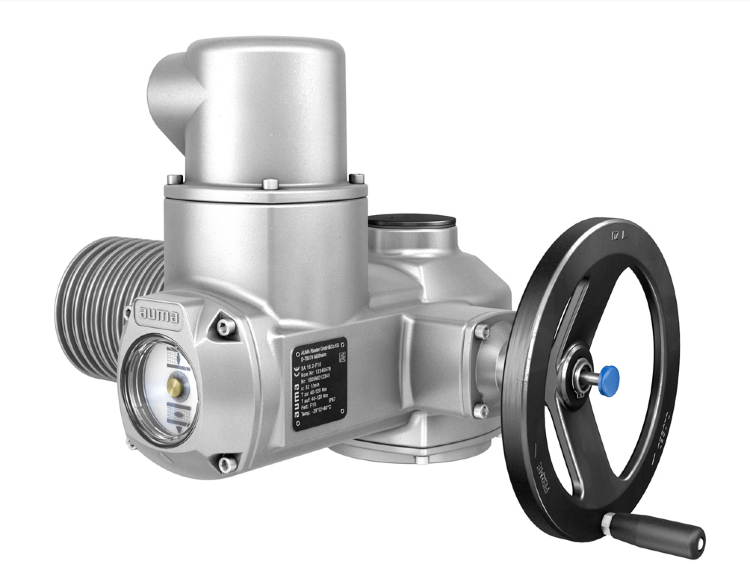

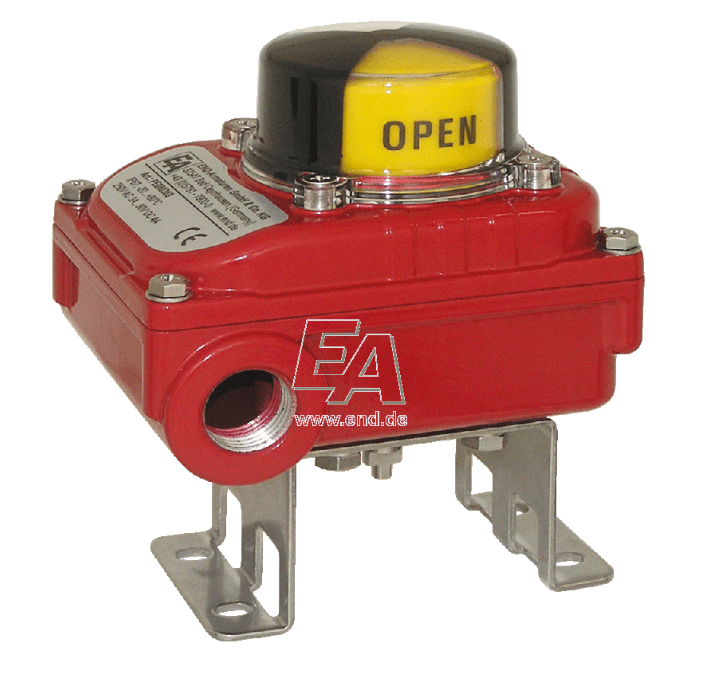

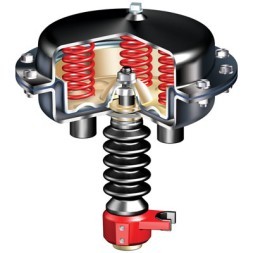

Various types of actuators are used for mechanized and automated valve control. When choosing them, the purpose of the valve, the intensity of the drive, the installation location of the valve, ease of maintenance, the relationship with various equipment, fire and explosion safety of the environment, as well as economic factors are taken into account. Electric drives with a multi-turn or single-turn actuator, electromagnetic drives, pneumatic and hydraulic drives (piston and diaphragm) are used.

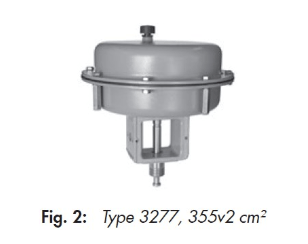

The most widely used electric drives are used for shut-off valves and for positional control. Pneumatic actuators with a diaphragm actuator used in control valves for continuous flow control in pipeline systems are widely used.

Electromagnetic actuators are used to control valves of small passage diameters, in particular to control valves used to control pneumatic actuators. Other types of drives are used less frequently.