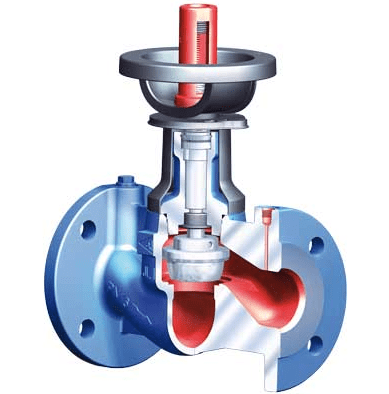

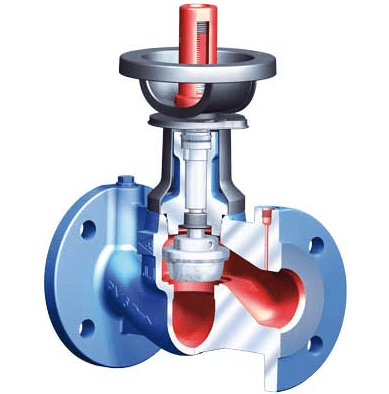

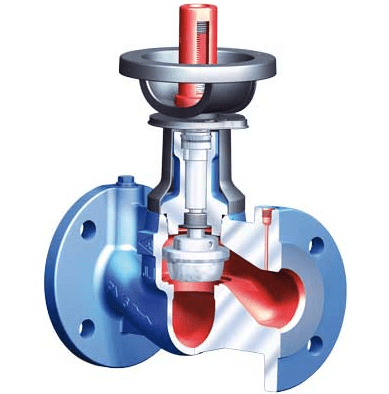

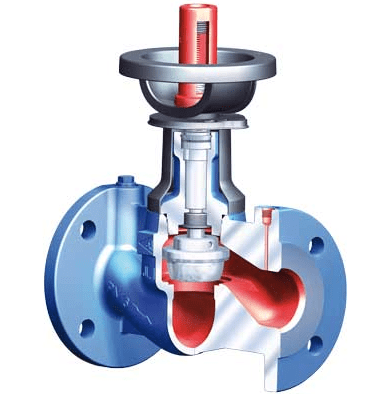

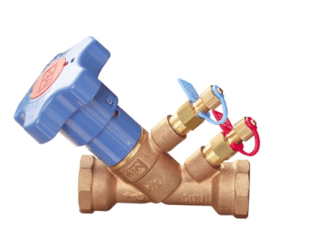

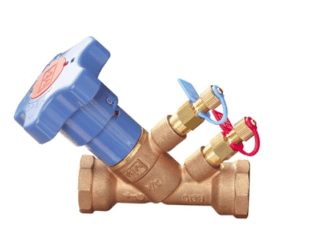

Balancing valves

Balancing valves ensure that the flow rate is maintained depending on pressure changes

The main task of such valves is to regulate the flow section for the passage of liquid at a given flow rate, which varies depending on the difference in pressure drop on the balancing valve.

How are valves arranged and for what purposes are they used?

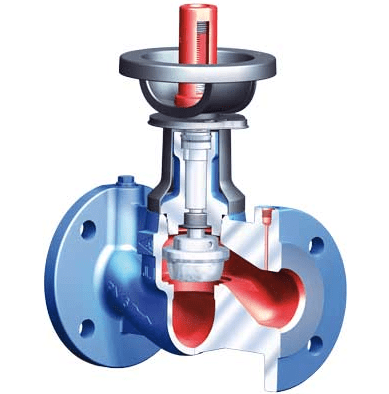

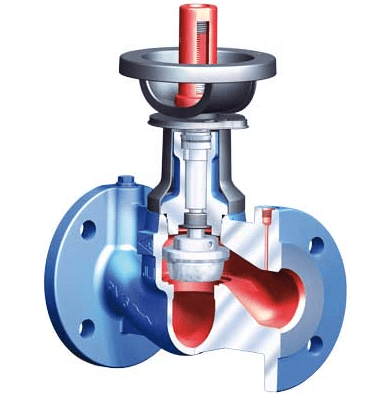

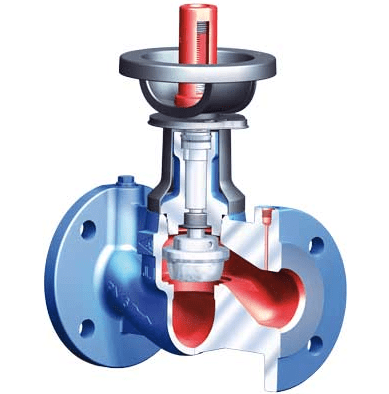

The balancing valve (valve) is a valve belonging to the shut-off and control type, which is mounted on pipelines to stabilize the temperature and pressure of the transported working medium.

The operation of the valve is based on the creation of a certain variable hydraulic resistance in the system in order to prevent exceeding the limit values of the medium and prevent an emergency situation. The creation of a balanced operating mode is the main indicator of the functioning of the entire system as a whole.

Balancing valves are used to accurately adjust the flow of heat or coolant in heating, cooling, air conditioning, ventilation, and hot water systems in accordance with calculations with an accuracy of +/- 5...10%.

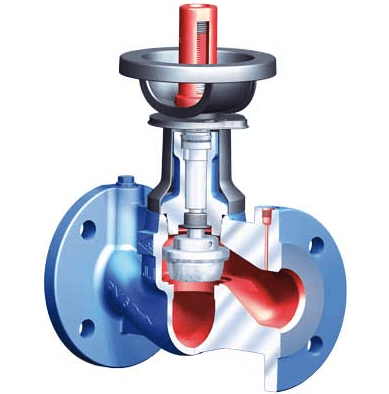

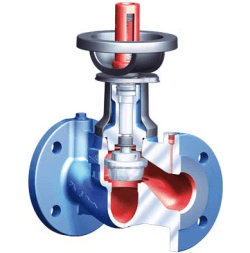

| Automatic balancing valves | They are installed on risers or horizontal branches of single-tube heating systems in order to maintain a constant flow of coolant in them. It is also a diaphragm regulator that maintains a constant pressure drop of the control element and ensures a certain flow of coolant through the valve. The valve is also a shut-off device. |

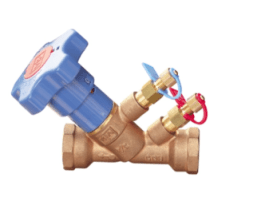

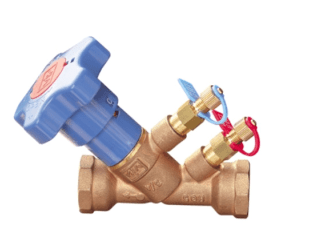

| Manual balancing valves | A valve-type device with a fixed position of its adjustment to the required throughput. They are used for single installation on heating mains, on risers. The shut-off valve may be used in conjunction with the balancing valve. |

Fluid flow measurements on balancing valves also allow for a complete system diagnosis and troubleshooting, such as blockages, improper installation of equipment, etc. before commissioning.

The correct distribution of heat or coolant allows you to get uniform heating or cooling of rooms, avoid noise on control valves, save energy and avoid premature equipment failure.

Advantages of installation:

- Multifunctionality of application as a locking device in order to stop the supply of coolant to the riser;

- The possibility of changing hydraulic settings, for example, the hydraulic resistance in the heating system, as a result of changes in the flow section of steel pipes over time.

- Easy maintenance: cleaning of the balancing valve is carried out without prolonged system shutdown.

- Precision settings: the balancing valve allows you to set a more uniform mode of cooling the medium, and during heating.

Call and order products from trusted manufacturers!