Rubber expansion joints

Rubber Pipeline Compensator

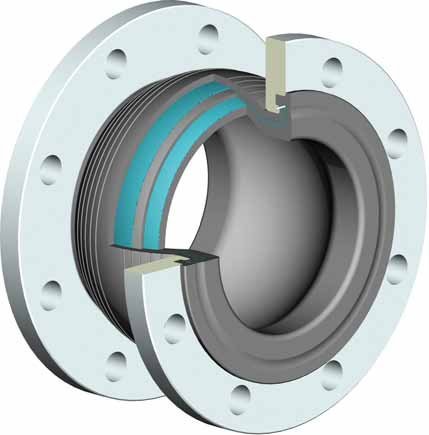

The main place of application of rubber expansion joints are pipeline systems with liquid media. The temperature of the liquid can reach 200 C. Standard versions have a resistance of up to 100-110 C. The main method of connection to the pipeline is a flange connection. To increase resistance to external influences, the rubber expansion joint can be packed in a special fire-resistant case.

Compensators are made of various elastomers (rubbers) and have cord reinforcement. Depending on the passing fluid, a suitable elastomer is selected. The most common materials are EPDM (ethylene propylene rubber) and NBR (nitrile butadiene rubber). EPDM rubber expansion joints are used for an aqueous working environment, NBR — for petroleum products and their derivatives. For chemically aggressive media (acids, alkalis, etc.), a special material is used — hypalon (sulfochlorinated polyethylene). To increase resistance to various chemically active media, special Teflon spraying can be used. Various angle limiters and connecting rods are used to increase the reliability of the flexible connection.

Rubber expansion joints are most widely used in water pipes, sewer pipelines, as well as in the petrochemical industry. Most manufacturers of pumping equipment recommend installing rubber expansion joints between the pump and the pipeline, which allows you to compensate for the vibration coming from the pump, thereby increasing the reliability and service life of the entire system, including other equipment connected to the pipeline. Recently, some European manufacturers have introduced rubber expansion joints with a special rubber composition in their line, which allows them to be used for drinking water pipes, as well as in the food industry.