Shut-off valves and valves

Shut-off valve: a wide range of products

A shut–off valve is a device for shutting off the working flow in pipeline systems when liquids move in one direction. The locking element regulates the supply of liquid medium (opens or closes), structurally has the form of a valve and moves in a parallel plane with the axis of the water flow. In case of an emergency in the system, the employees responsible for the workflow must close the shut–off valve, repair this section, and then resume the liquid supply. Also, individual sections may overlap during the entire period of operation for maintenance.

The products can be of different lengths, diameters and weights, but they are all designed for a long–term service life - up to 50 years, capable of operating under different temperature conditions (high and low values).

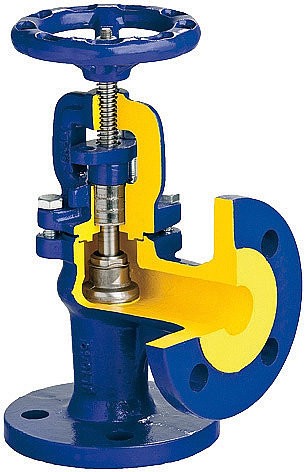

The device and the principle of operation

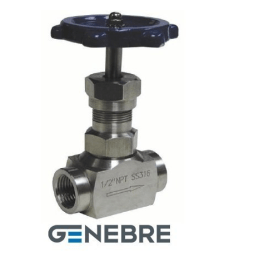

Structurally, this type of shut-off valve consists of:

- The handle with which the rotational movements are carried out.

- The main body, from which two nozzles come out (one works at the inlet of the working medium, the second at the outlet).

- Spool: the purpose of this element is to block the supply of a gaseous or liquid substance.

- The spindle is a device for transferring force from the handle (during rotation) to the spool.

According to the principle of operation, the shut-off water valve is an absolutely simple and understandable device. The person turns the handle, the spindle transmits the torque to the spool, which in turn covers the entire diameter of the pipeline at this point. As a result, water, fuel, aggressive media or oil stop flowing through the pipeline system.

Classification by material

According to the material of manufacture, the products are divided into: brass, cast iron and steel. Let's consider the features and advantages of rebar made of each material:

- Brass. You can buy a brass shut–off valve for use in a liquid medium – up to +70 degrees, for steam - up to + 200 degrees. By design, it can be angular, through-flow and direct-flow. A reliable and durable product operates at high operating pressure values and is resistant to sudden fluctuations in this characteristic. The product is installed on any sections of the pipeline system in any position, the operability of the device does not depend on its location.

- Cast iron. One of the most popular types of shut-off and control valves is cast iron. There are two types according to the method of attachment: a flanged shut-off valve (attached to the system with nuts, bolts and other threaded connections) and a shut-off coupling valve (installed in the pipeline system using a special coupling that has an internal threaded connection). The advantages of the products: a large coefficient of resistance, an elementary design combined with a small stroke of the spool, excellent performance, versatility in terms of application. When choosing, several parameters should be taken into account: the range of pressure parameters, the ability to operate at certain temperatures, and the diameter of the structure itself.

- Steel. A steel shut-off valve is used in sections of technological lines and pipelines transporting not only water and steam, but also other working media: from natural and liquefied gas to ammonia, carbon dioxide and corrosive substances. The products are of high quality and reliability, and can be used under the most stressful conditions, unlike previous types of fittings. The maximum allowed temperature range is +425 degrees, the possible operating pressure is above 6.3 MPa. Advantages: withstands the maximum possible pressure and temperature parameters, is maintainable due to its simple design, can be mounted in any position relative to planes.

Advantages of cooperation with the Salutech company

You can order any equipment and devices for various industries on our website. We guarantee that the price for the shut-off valve will be lower than the market price, we are responsible for the quality and provide warranty and post-warranty service. Our specialists are always happy to help with the selection of products and arrange delivery.