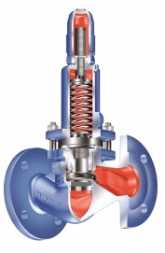

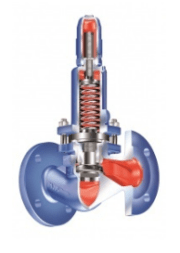

Bypass valves

A bypass valve (overflow valve) is a device designed to maintain the pressure of the medium at the required level by passing it through a branch of the pipeline.

The medium can be liquid or gaseous.

The bypass valve maintains pressure in the system by continuously removing liquid (gas), which differs from a safety valve, which limits the increase in pressure in the system beyond the set one by a single or periodic removal of liquid (gas) from the system.

Externally, the bypass and safety valves may not differ from each other.

Just like the pressure reducing valve, the bypass valve maintains constant pressure in the system. However, the bypass valve maintains a constant pressure at the inlet to the valve ("before itself"), and the pressure reducing valve maintains a constant pressure at the outlet ("after itself").

Controlling the flow of working media is the main and main task of the control valve. In this context, the bypass valve is responsible for maintaining the required pressure to its installation location by automatically discharging excess pressure from the main line to the drain or bypass.

By its design, the bypass valve refers to direct-acting control valves. The control signal is received from the working medium itself and is transmitted through the diaphragm and valve stem to the plunger to regulate the opening level. It should be borne in mind that since this is a control valve, and not a shut-off valve, in most cases there is a certain leakage in the seat of the valves, which depends on the type of seal and the quality of the valve itself.

The bypass valve is selected based on the following basic parameters:

- Working environment. It is very important to understand that a bypass valve is a complex structure consisting of many parts. Various elastomer seals are used for the tightness of the valve and its operation. Incorrect selection leads to valve failure with various consequences for technology, the environment and humans.

- Physical parameters of the working environment. Based on its viscosity, fluidity, the presence of abrasive and the aggregate state, a bypass valve with a specific design of the seat, valve plunger and useful membrane area is selected, and the operating temperature of the medium affects the materials of the valve and seals.

- Operating parameters of the working environment. The main parameter by which the bypass valve is selected is its throughput. Only by knowing the pressure that needs to be maintained, the pressure of the medium behind the valve in the discharge line, as well as the flow rate, can the valve be selected correctly.

- Additional conditions. It is necessary to take into account not only the specified parameters, but also the ratio of inlet and outlet pressure, installation location, and the speed of working media in the system. The wrong choice leads to the occurrence of cavitation, the inability to regulate and further destruction of the valve. In addition, do not forget about the installation location of the valve – it also affects the valve.

After preliminary calculation of the throughput, sealing materials and housing, you can choose a bypass valve according to the manufacturer – who can offer a valve for the design parameters, as well as taking into account the installation location and other significant conditions.