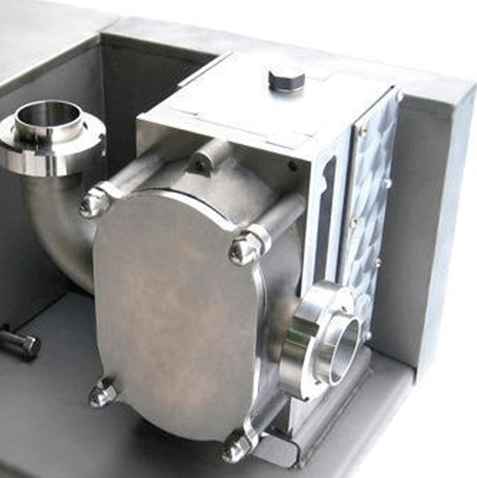

Cam Rotary pumps

The cam (rotary) pump is designed for pumping food products, pharmaceutical substances and chemical media with medium and high viscosity. The devices are widely used in the field of chemical, food, pharmaceutical industry, medicine, electroplating. The main parts of the pump are made of high-quality stainless steel. If necessary, the food cam pump can additionally be equipped with a frequency converter, variator, bypass, noise protection or cooling casing. The equipment is manufactured in accordance with GOST 17398-72 using multifunctional CNC machines. The equipment has a capacity from 0.5 to 50 kW with a maximum supply of 300 to 90,000 liters of pumped substance per hour. Most models generate a pressure from 5 to 20 bar at the outlet.

The principle of operation of the cam pump

The rotary cam pump refers to volumetric mechanisms. The principle of operation of the unit is based on the volumetric displacement of the pumped medium. The device has a relatively low rotational speed compared to vortex or centrifugal pumps. This design allows the use of rotary cam equipment for pumping media requiring delicate handling. The equipment is capable of developing sufficiently high pressure for pumping highly viscous liquids.

Two stainless steel cams are installed inside the pump, which rotate on top of each other. During rotation, a vacuum is created inside the suction nozzle. The pumped substance enters the working chamber and, under the influence of the mechanical movement of the cam, is pushed around the rotor to the outlet pipe. During pumping, the rotor does not come into contact with the working medium, which ensures a high level of hygiene.

Advantages of cam pumps

Hygienic rotary cam pumps, which can be purchased in our online store, have the following advantages:

- The absence of wearing parts in the design;

- Designed for continuous 24/7 operation;

- Hot steam treatment and disinfection are possible;

- Robust housing that can withstand static and dynamic loads;

- Resistance to wear, corrosion, mineralization;

- The possibility of pumping media with inclusions up to 30 mm;

- Pumping of working media with temperatures up to +150 C;

- Installation in vertical and horizontal position;

- Minimum maintenance requirements;

- Low noise level during operation.

The cam food pump pumps products in a uniform flow without disturbing the structure of the moving medium. The device can work for a short time without filling. The equipment is integrated into any production lines and has an extremely low cost of operation.

Scope of application of cam pumps

A cam pump can be purchased for pumping products in the food industry. They are used to supply dairy and fermented milk products, cheese and curd grains, chocolate mass, confectionery fillings, concentrates, margarine, fat, pates, minced meat, etc. to production lines. In the field of conservation, devices are widely used to supply brines or marinades to injectors. The equipment can be used both for feeding food media and for their dosing.

Cam pumps are also in demand in the chemical, cosmetic, pharmaceutical, electroplating, paper and pulp industry, water treatment and in the production of paints and varnishes.

Where to buy a cam pump

The price of the equipment depends on the capacity and configuration. The Salutech company offers equipment for the food and chemical industry with delivery to all regions of Russia. Here you can choose a rotary cam pump manufactured in the EU with the required capacity. The units are guaranteed. We offer selection assistance, operational advice, technical support, prompt delivery and low prices.