Drives

Drive equipment as part of industrial installations.

The drive equipment consists of technical devices that are used to transmit rotational or translational motion to the working bodies of technological equipment.

What is included in the drives?

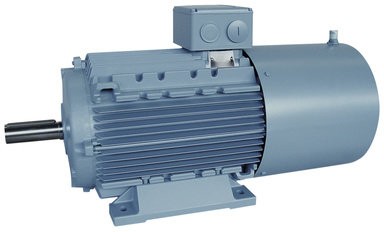

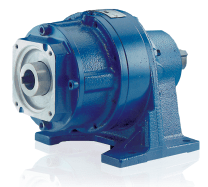

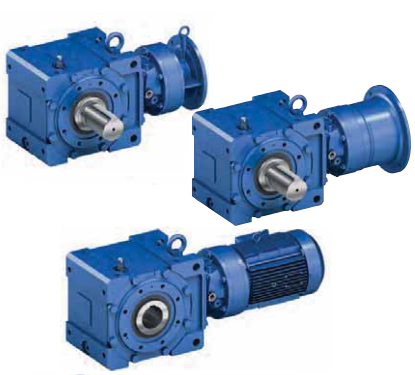

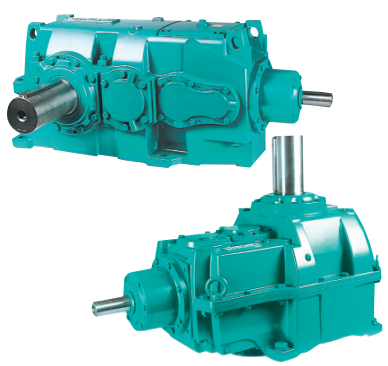

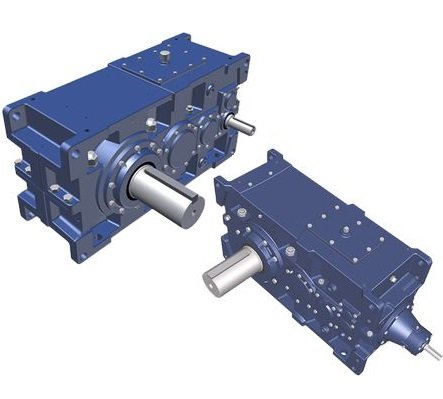

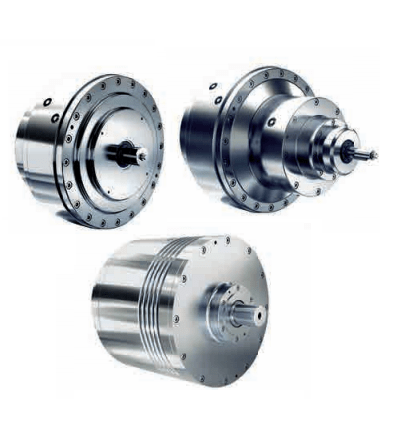

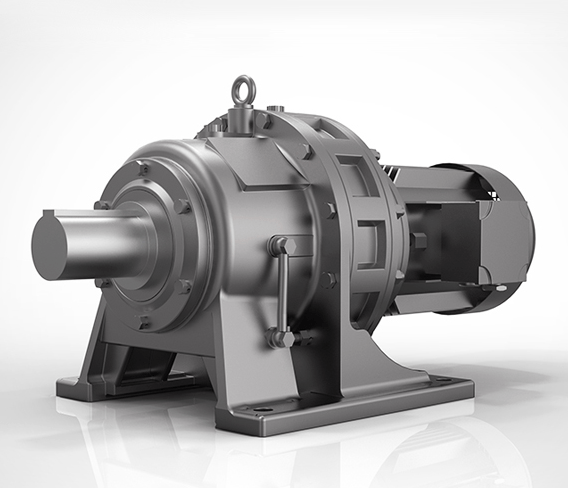

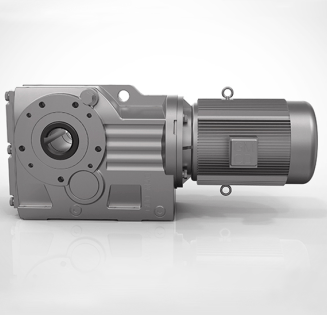

All equipment is represented by a wide range of servo motors, electric motors, gearboxes and gear motors.

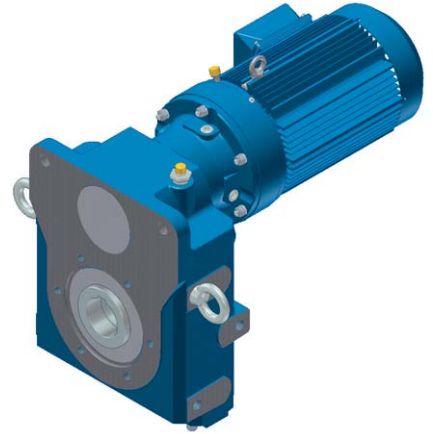

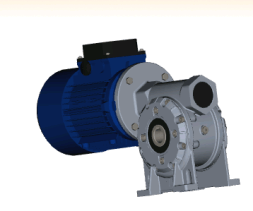

Structurally, the drive equipment consists of devices for preparing electrical energy - a drive that generates force, and a transfer and conversion unit (for example, a gearbox).

All three structural elements can be assembled in one housing or installed separately.

In order for the drive device to be able to do its job, only the drive is enough, the other components are designed to improve the quality of this work.

To regulate the speed of electric motors, gearboxes, gear motors and servos, frequency converters (PE) and soft-start devices (UPP) are offered.

Frequency control of an electric motor is effectively used in industrial enterprises, in the field of energy, utilities and other areas to automate production processes, save on energy consumption and other production resources, and improve the quality of products.

The use of soft-start devices (UPP) and frequency control (PE) of engine rotation in pumping units provides a number of advantages such as, for example, smooth start and stop of the engine eliminates the harmful effects of transients (such as hydraulic shock) in pressure pipelines and technological equipment; the engine is started at currents limited at the nominal level values, which increases the durability of the engine, reduces the requirements for the power of the supply network and the power of the switching equipment; it is possible to modernize existing technological units without replacing pumping equipment and practically without interruptions in its operation.

| Types of drive equipment |

|

To date, electromechanical drive devices have become the most widespread in industrial equipment.

There is practically no fundamental difference between them, but the performance characteristics are very different. The impact of the drive equipment on the working bodies is unidirectional, reversible and multi-coordinate (reciprocating) in nature. At the same time, its force (kinetic energy communicated to the working body) can be conditional (constant) or adapted to the characteristics of a particular equipment.

The adaptation of the drive technology is carried out by the method of external adjustment or self-regulation of the drive device.

Contact Salutech for advice and if you need to choose a drive or control!

Drive equipment as part of industrial installations.

The drive equipment consists of technical devices that are used to transmit rotational or translational motion to the working bodies of technological equipment.

What is included in the drives?

All equipment is represented by a wide range of servo motors, electric motors, gearboxes and gear motors.

Structurally, the drive equipment consists of devices for preparing electrical energy - a drive that generates force, and a transfer and conversion unit (for example, a gearbox).

All three structural elements can be assembled in one housing or installed separately.

In order for the drive device to be able to do its job, only the drive is enough, the other components are designed to improve the quality of this work.

To regulate the speed of electric motors, gearboxes, gear motors and servos, frequency converters (PE) and soft-start devices (UPP) are offered.

Frequency control of an electric motor is effectively used in industrial enterprises, in the field of energy, utilities and other areas to automate production processes, save on energy consumption and other production resources, and improve the quality of products.

The use of soft-start devices (UPP) and frequency control (PE) of engine rotation in pumping units provides a number of advantages such as, for example, smooth start and stop of the engine eliminates the harmful effects of transients (such as hydraulic shock) in pressure pipelines and technological equipment; the engine is started at currents limited at the nominal level values, which increases the durability of the engine, reduces the requirements for the power of the supply network and the power of the switching equipment; it is possible to modernize existing technological units without replacing pumping equipment and practically without interruptions in its operation.

| Types of drive equipment |

|

To date, electromechanical drive devices have become the most widespread in industrial equipment.

There is practically no fundamental difference between them, but the performance characteristics are very different. The impact of the drive equipment on the working bodies is unidirectional, reversible and multi-coordinate (reciprocating) in nature. At the same time, its force (kinetic energy communicated to the working body) can be conditional (constant) or adapted to the characteristics of a particular equipment.

The adaptation of the drive technology is carried out by the method of external adjustment or self-regulation of the drive device.

Contact Salutech for advice and if you need to choose a drive or control!