Electric motors

Electric motors are the basic elements of industrial equipment that drive the drives of machine tools, conveyors, circulation pumps, cranes, ventilation systems and other high—tech mechanisms used in various industries.

The device and the principle of operation

The functionality of electric motors is based on the consumption of electricity, due to which the mechanism performs translational rotational movements. In industry, such installations power machine tools, cranes, circulation pumps and other devices responsible for various production processes. Passing through a metal conductor (coil), an electric current "projects" a powerful electro-magnetic field that creates a voltage in a "closed circuit".

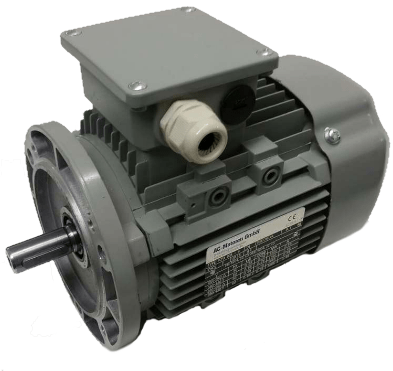

The design of an industrial electric motor consists of 3 mandatory elements:

Body. The main purpose of the housing is the compact placement of all parts of the electric motor. This structural element is made of a high-strength metal alloy capable of withstanding "extreme" temperature changes. Due to this property of the cladding material, the equipment does not overheat and maintains high efficiency throughout the entire production process.

The stator. The stator works in an inseparable "bundle" with the winding. The first device creates an electro-magnetic field, the second is responsible for the uninterrupted transmission of current "inside" it. These parts are placed in the "core" (or "anchor") the housings are fixed with bearings that reduce the resistance to the friction force. Such an engineering "scheme" avoids rapid wear of individual equipment elements and significantly prolongs their service life.

Winding. The main working processes of converting electrical energy into mechanical energy are carried out in the winding. It is in the winding of the electric motor that the electromotive force (EMF) is induced and an electric current appears, creating electromagnetic forces when interacting with a magnetic field.

Types of industrial electric motors

Depending on the method of energy transmission through the windings, electric motors are divided into AC and DC motors. The catalog of our company presents single-phase, two-phase, three-phase, asynchronous and other modifications of installations with high performance and designed for various fields of industrial production.

According to the degree of IP protection, three versions of the asynchronous motor are provided: IP44, IP54, IP23.

The first digit indicates the degree of protection provided by the engine shell from the penetration of foreign solids.

The second digit means the degree of protection provided by the asynchronous motor shell from the harmful effects of penetrating water.

The operating modes of asynchronous electric motors are divided into long-term (S1), short-term (S2), and repeated-short-term (S3).

Fields of application of electric motors

Electric motors are applicable in all "sectors" of modern industry. They are especially in demand in industries where ventilation systems, refrigeration units, locksmiths and lathes, lifting and conveyor mechanisms, construction, finishing and grinding equipment are used.

Order an industrial electric motor

The Salutech company is a reliable supplier of high—tech equipment for large industrial enterprises. Our range includes electric motors Damage, AIR, AIRM and other modifications of installations with unique technical characteristics and a high degree of protection against mechanical damage, wear and corrosion. Our products are certified and comply with European quality standards.