Пневматический молот

Design features and operating principle of the pneumatic hammer

A pneumatic hammer is a device for the forging and stamping industry, having a number of strokes from 95 to 225 units per minute and a mass of impact elements from 1000 to 50 kg, respectively. The main purpose of the equipment is to automate processes in the metalworking market segment in combination with increased productivity at the production facility. The equipment is designed to perform a large list of operations for hot volume forging due to the transformation of a mechanical type of energy into a shock weight load. It is suitable for medium-scale and small-scale production using various alloys and metals.

Features of the pneumatic hammer design

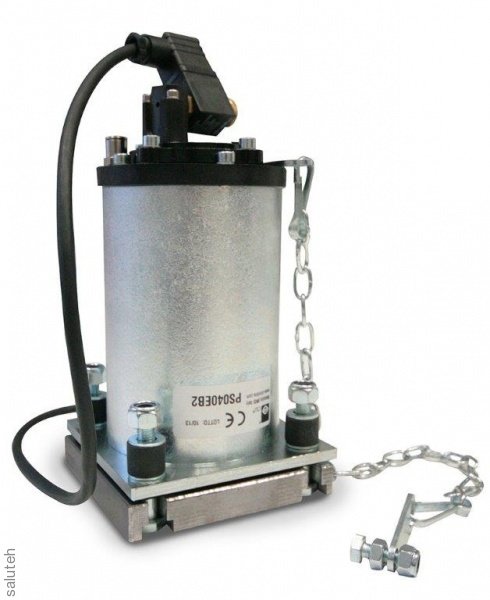

According to its design, the pneumatic hammer consists of:

- Drive: electric motor to ensure uninterrupted operation, gearbox, belt drive, connecting rod, crank shaft.

- A working cylinder with a rod, piston, and upper striker.

- A compressor cylindrical base with a built-in piston.

- Other details: control valves, handles, pedals, etc.

Due to the air distribution mechanism, the hammer can operate at idle and in several other modes: sequential strikes, holding the part on weight, and pressing forging mode.

The principle of operation of pneumatic hammers

The principle of operation of a pneumatic hammer at any price and with any performance is based on the impact of the impact mass of the falling mechanism. Due to the convenience of control, the workpiece is passed from three sides, it is possible to adjust the frequency and force of impact.

Application areas and advantages of pneumatic hammers

The main field of application of the pneumatic unit is forging and stamping, where it can be used for bending, drawing, chopping and punching holes. The ease of impact control allows you to create parts and workpieces of a wide variety of shapes.

The advantages are interrelated with excellent technical characteristics:

- Low weight combined with reliable design

- Versatility of operation

- Impact accuracy

- Simplicity and ease of management

- The ability to process from three directions

- Precise dosing of rolled metal

- High efficiency

Order pneumatic equipment

The most profitable way to buy a pneumatic hammer is at dealer prices in the Salutech company. The catalog contains a sufficient range of products from trusted manufacturers. The user-friendly interface of the site allows you to purchase any product in one click.