Vibrating screens

Vibrators for laying concrete and screed

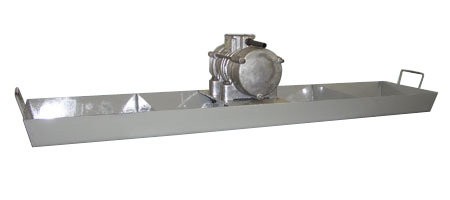

A vibrating rack is a tool used when laying a concrete surface. During operation, the rail rams the concrete mixture, thereby eliminating the appearance of internal voids in the concrete that can lead to holes and cracks. Thus, the surface becomes denser, smoother and smoother, and the finishing and laying of other materials on concrete is simplified.

Types of concrete vibrators

There are many types of vibrators on the market that differ in power, profile length, working surface dimensions and other parameters.

In our store you can find and buy the following types of vibrators:

- Petrol ones.As the name suggests, these vibrators run on a gasoline engine. Since exhaust gas is released during the operation of the gasoline vibrating screen, it can only be used in open areas. Due to their large size, gasoline models are successfully used for surface treatment of a large area. A gasoline vibrating rack allows you not to depend on the availability of an electric grid, but fuel will be required for its operation.

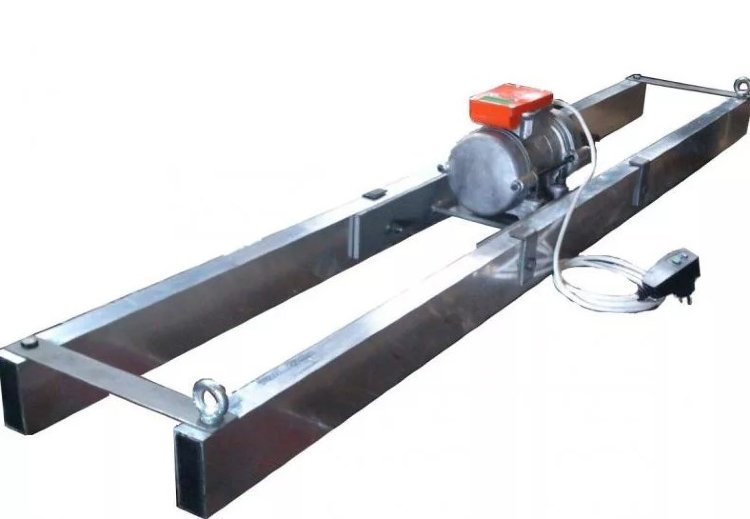

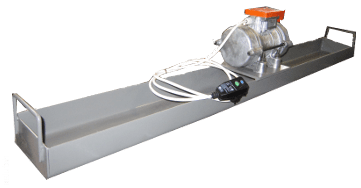

- Electric. A compact mobile device suitable for indoor use. It is powered by the mains, does not create noise and exhaust gases during operation. Most models require constant connection to a standard 220 V power supply

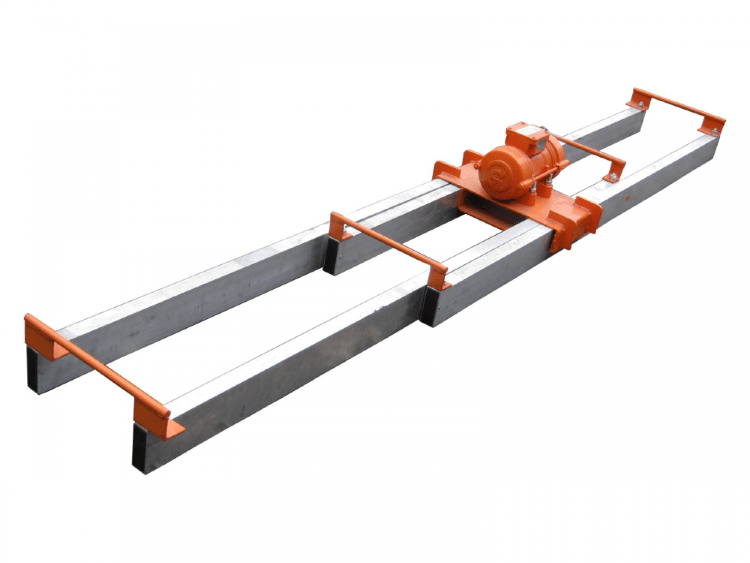

- Telescopic.Such vibrators are distinguished by a sliding frame of two guide rails. The telescopic rail is easy to assemble and expand to the desired size, allowing you to process an area up to 10 meters wide.

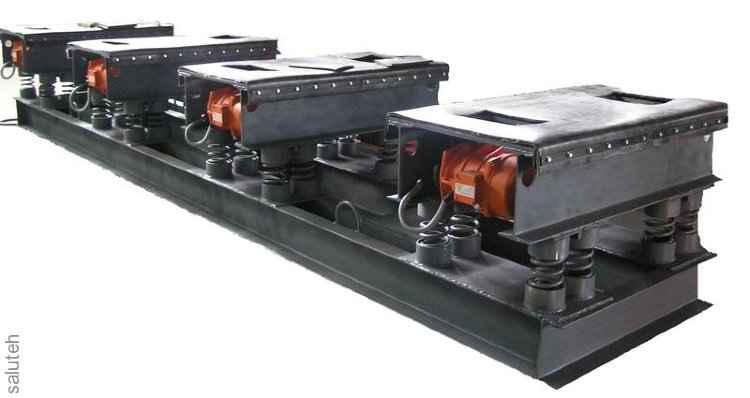

- Sectional.These models of vibrators consist of several parts or sections: head, intermediate and final, equipped with a handle or winch fasteners. Such a vibrating rack is used to work on large areas.

The design of the vibrating rack

Structurally, the tool consists of three parts:

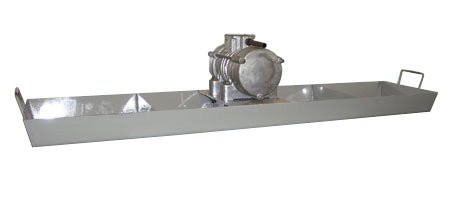

- Steel frame. The maximally lightweight frame of the structure allows minimizing the pressure on the concrete surface. Convenient handles or fasteners are designed for control, with which you can move the vibrating rack in the right direction.

- Rule or rake. A structural element that aligns the concrete surface. The rail can be of different lengths, depending on the design and the performance of a specific task. Slats with a length of 80 to 300 cm or more are usually used. The use of longer slats facilitates the processing of extensive surfaces.

- Engine. The presence of a gasoline or electric motor makes it easier to work with the tool, so that one person can easily control the vibrating rack. The motor creates a continuous vibration, due to which the concrete mixture is evenly compacted. Uniform continuous vibration makes it easy to treat the surface without jerks and irregularities during operation.

The principle of operation and areas of application

The vibrating screen is used in work on leveling concrete paths, self-leveling floors, concrete platforms and other similar coatings. The use of a vibrating rail in operation significantly improves the quality of concrete laying with large volumes of work.

The use of a vibrating rack for laying concrete has a number of advantages:

- Convenience and ease of use.

- High power.

- The ability to use different power sources.

- The simplicity of the design.

- High performance.

- An affordable price.

The principle of working with a vibrating rack is very simple: the operator puts the tool on the surface and turns on the engine. Then the worker pulls the vibrating rack towards himself, thereby tamping the concrete surface. The vibration motor sets a certain oscillation frequency, which can be adjusted depending on the need. During operation, the vibration of the engine is transmitted to the profile of the vibrating rack, and through it to the top layer of concrete. Vibration removes air bubbles from the concrete mix, gives it additional density and strength.

During operation, the surface level is periodically measured to prevent deviations from the set parameters.

On the website of the Salutech company, you can buy vibrators for laying concrete from various manufacturers. We offer certified industrial equipment and help you choose the best equipment for your needs in terms of price and characteristics.