Floating vibrating screens

Floating vibrating rack is a construction equipment for ramming cement-based building mixes. It is produced in accordance with TU 4833-004-00239942-2003. You can order floating vibrating screens for concrete that meet the requirements of the SNiP and technical Regulations of the Russian Federation No. 753 "On the safety of machinery and equipment".

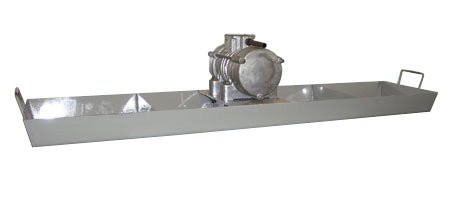

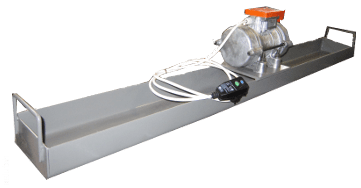

The design and principle of operation of a floating vibrating rack

The main part of the floating vibrating rack for concrete mortars is a vibrator with a power from 0.1 to 0.55 kW, which is connected to the leveler. For convenient use, the equipment is equipped with a height-adjustable handle with clamps. There is an ON/OFF button switch on the handle. The protection of the worker during operation of the vibrating rack is provided by an RCD mounted on an electric cable.

When the equipment is turned on, the unbalancing elements of the vibrator begin to rotate, which cause vibrations in the concrete mass, which leads to its compaction.

Advantages of floating vibrators

Electric floating vibrators have a number of advantages in comparison with gasoline ones:

- Ease of use;

- suitable for ramming low-moisture materials;

- They can work in hazardous areas;

- high quality sealing of building mixes;

- engine overheating protection;

- No exhaust, can be used indoors;

- smooth and high-quality concrete coating.

Scope of application of floating vibrators

Floating vibrators are used for ramming and leveling mortars in monolithic, road construction. The equipment is used for filling concrete structures with a formwork method, for the installation of floor screeds, industrial sites, foundations, and roadways.

The use of devices makes it possible to multiply the strength of concrete and evenly distribute it inside the formwork.