Company Vahle has developed a wide range of motor drums for automatic winding of flexible power cables and control cables. They are actively used to organize the electrification of mobile equipment, in particular for various types of cranes: gantry, gantry, shipboard, dock, hoists, grabs, trolleys and other lifting and transport devices.

The coil is powered by a built-in high-torque electric motor, and can also be equipped with an asynchronous magnetic coupling, which provides the required force to pull the cable in any direction and any speed values within the established norms. Standard contact rings are powered by 690 V AC and 900 V DC, a 500 V control unit. T there is a range of models for high-voltage applications voltage 6/10 kV. Drums with other electrical data are only available on request.

Types of electric drives used:

- high-torque motor with a closed-loop rotor

- high-torque motor with contact rings or with variable step control resistor

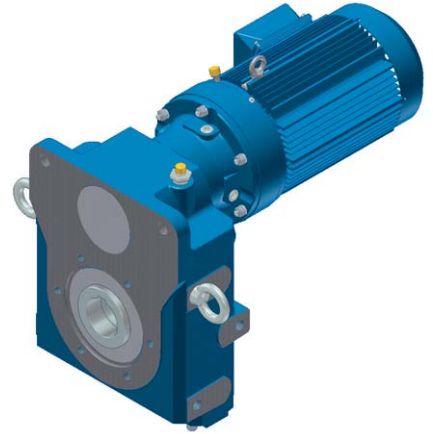

- AC motor with magnetic coupling (LTM series)

The housing in the basic design is protected from dust and water droplets, higher requirements for the shell can be implemented on request. To protect against corrosion, steel drums are galvanized or a primer and a finishing layer of epoxy resin varnish are applied to the surface.

In addition to general purpose cable drums, specialized versions are always available for special conditions and requirements: hot climates, marine applications, aggressive environments, explosive zones. As well as varieties for winding flat cables, hoses (supply of water, air, gases), steel ropes and other types.

Special series of high-speed coils and series for heavy duty operation with high-torque motors with electronic control, hydraulic drives with constant or variable torque have also been developed.

Technical characteristics of cylindrical motor drums for cable winding Vahle LT /LTM

- Max. speed of travel or lifting: up to 80 m/min;

- Max. boost: up to 0.2 m/s²;

- Diameter (shaft): 280 - 800 mm;

- Diameter (total): 450 - 1400 mm;

- Protection class: IP 54.

Standard sizes of cylindrical motor drums for cable winding Vahle LT /LTM

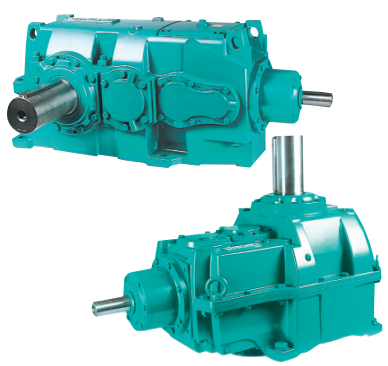

chain transmission mechanism

для горизонтальной намотки на высоте до 1,5 м: LT 28 N…-K, LT 38 N…-K …-KG, LT 50 N…-K …-KG, LT 50. 1N…-K …-KG, LT 70 N…-K …-KG

для вертикальной работы: LT 28 S…-K, LT 38 S…-K …-KG, LT 50 S…-K …-KG, LT 50. 1S…-K …-KG

gear transmission mechanism

for horizontal winding at a height of up to 1.5 m:

LT 28 N ...- 6, LT 38 N ...- 6, LT 50 N ...- 6 ...- 8, LT 50. 1N ...- 6 ...- 8, LT 70 N ...- 8, LT 80 N ...-10

LTM 38 N ...- 6, LTM 50 N ...- 6 ...- 8, LTM 50. 1N ...- 6 ...- 8, LTM 70 N ...- 8, LTM 80 N ...-10

for vertical operation:

LT 28 S ...- 6, LT 38 S ...- 6, LT 50 S ...- 6 ...- 8, LT 50. 1S ...- 6 ...- 8

LTM 38 S ...- 6, LTM 50 S ...- 6 ...- 8, LTM 50. 1S ...- 6

flat transmission

для горизонтальной намотки на высоте до 1,5 м: LTM 28 N ... -95/... MA S, LTM 38 N ... -95/... MA S, LTM 50 N ... -95/... MA, LTM 50.1 N ... -95/... MA

important! To select a motor drum model, it is necessary to take into account the technical parameters of the cable used (the dimensions of the current line, the number of conductors, diameter, weight and minimum bending radius), the required active length and the maximum operating speed of the connected equipment. Our engineers will definitely help you make the right choice.

You can buy cylindrical motor drums for cable winding from Vahle, find out the price and more information about the product by contacting our specialists.